果壳活性炭产品介绍

果壳活性炭是以核桃壳、杏壳、枣壳等优质坚果壳为原料,经筛选分级、低温炭化(500-700℃)、高温活化(800-1000℃)、精制提纯等工艺制成的多孔吸附材料。其原料具有天然致密的木质结构,经特殊工艺处理后形成发达的微孔体系,兼具吸附容量大、强度高、易再生等优势,在饮用水净化、食品加工、贵金属提取等领域应用广泛,是性价比与性能平衡的优选吸附材料。

一、外观特征

产品呈黑色不规则颗粒状,颗粒形态因原料不同略有差异,核桃壳基产品颗粒更饱满,杏壳基产品边缘稍锐利,整体无明显棱角。常规粒径规格覆盖6-12目、12-24目、24-48目,其中12-24目为通用型规格,24-48目适用于精细净化场景。颗粒表面粗糙多孔,触感干涩,无油腻感,在强光下观察可见细微孔隙开口。堆积密度为0.48-0.60g/cm³,介于椰壳活性炭(0.42-0.50g/cm³)与煤质活性炭(0.55-0.75g/cm³)之间。优质产品颗粒完整性≥96%,经机械振动测试后磨损率≤2.5%,在水中浸泡后初始浮性良好,吸附饱和后缓慢沉降,无明显粉化现象。

二、核心特性

1. 吸附性能均衡:BET比表面积为900-1300m²/g,微孔(1-2nm)占比75%-85%,中孔(2-50nm)占比10%-20%,孔隙结构适配小分子污染物与部分中大分子物质吸附。关键性能指标表现优异,碘吸附值为850-1100mg/g,亚甲基蓝吸附值为120-180mg/g,苯酚吸附值≥35mg/g,在饮用水净化中对余氯去除率达99.5%以上,对有机物的吸附速率较煤质活性炭提升20%-30%。

2. 机械强度可靠:机械强度≥94%,其中核桃壳基产品强度可达96%,能耐受水处理反冲洗、流化床吸附等动态工况,在自来水厂滤池反冲洗(冲洗强度10-15L/(m²·s))过程中,破碎率控制在1%以内,减少炭粉对出水水质的影响。耐磨性能优异,长期循环使用中炭耗量低,降低运行成本。

3. 化学特性稳定:产品pH值稳定在6.0-9.0,呈中性范围,不会改变处理介质的酸碱度。硫含量≤0.2%,氮含量≤1.0%,化学惰性强,不与水中常见有机物、重金属离子发生化学反应。食品级产品严格遵循GB/T 12496-2015标准,重金属含量极低(砷≤5mg/kg、铅≤20mg/kg、汞≤0.1mg/kg),符合食品安全要求。

4. 再生性能良好:采用高温蒸汽再生工艺(350-450℃),再生后吸附容量可恢复至初始值的80%-85%,再生周期为吸附周期的1/3,可重复再生5-8次。相较于椰壳活性炭,再生能耗降低15%-20%,综合使用成本更具优势,尤其适用于大规模连续运行系统。

三、应用领域

1. 饮用水净化领域:在自来水厂深度处理中,12-24目果壳活性炭填充滤池,可有效去除水中余氯、异味、卤代烃及微量农药残留,处理后水中余氯含量≤0.05mg/L,异味物质阈值降至20嗅阈值单位以下,符合GB 5749-2022生活饮用水卫生标准。家用净水器中,24-48目精细颗粒炭作为核心滤材,单支滤芯处理水量可达2-5m³,保障家庭饮水安全。

2. 食品与饮料工业:在制糖工业中,用于蔗糖、果葡糖浆的脱色精制,投加量0.2%-0.4%即可去除糖液中的焦糖色素、类黑精,提升产品白度至92%以上。酒类生产中,用于黄酒、果酒的除杂澄清,吸附酒中的醛类、酯类杂质,使酒体口感更纯净,保质期延长6-12个月。饮料行业中,用于果汁脱涩、茶饮料除杂,去除单宁酸及苦涩物质,保留原有的风味与营养成分。

3. 贵金属提取领域:在黄金、白银等贵金属堆浸与炭浆法提取中,6-12目果壳活性炭可高效吸附氰化浸出液中的金氰络离子、银氰络离子,金吸附容量达350-500g/t,银吸附容量达800-1200g/t,解吸效率≥97%,适用于中低品位金矿及银矿的提取工艺,在河南、山东等矿业产区应用广泛。

4. 工业废水处理:在化工废水处理中,用于去除苯、甲苯、酚类等有机污染物,COD去除率达35%-55%;印染废水处理中,对活性染料、酸性染料的脱色率达80%-90%;电镀废水处理中,对铬、镍、铜等重金属离子吸附去除率超90%,常作为深度处理单元,使废水达到排放标准。

5. 气相净化领域:在工业废气处理中,用于吸附涂装、印刷行业排放的VOCs,对苯、乙酸乙酯的吸附效率达80%-90%;在室内空气净化中,作为活性炭包、空气净化器滤网核心材料,对甲醛、TVOC的吸附量达70-120mg/g,有效改善室内空气质量。此外,还可用于防毒面具滤毒罐,吸附有毒气体,保障作业人员安全。

指标基本参数(可按客户需求定制):

型号 | 指标(可定制) | 用途 |

TY-YKL1(椰壳颗粒炭) | 粒度:10-24目 | 用于锅炉水、凝结水、电子半导体行业高纯水精制 |

TY-YKL2(椰壳颗粒炭) | 粒度20-48目 | 净水器滤芯、饮料、酒类、食品、高纯水应用 |

TYK-TKL(桃壳颗粒炭) | 粒度:20-40目 | 用于酒类脱色、提纯,去除苦味改善口感 |

TY-YKF(椰壳粉末炭) | 粒度:150-325目 | 饮用水处理、食品脱色提纯与精制、药剂添加、污水处理、提炼贵金属 |

TY-XKF(杏壳粉末炭) | 粒度:150-325目 | 饮用水处理、污水处理、食品脱色提纯、药剂添加 |

TY-TKF(桃壳粉末炭) | 粒度:150-325目 | 饮用水处理、污水处理 |

(注:可酸洗、水洗、改性、载银处理)

天源品质控制:按国家标准控制。

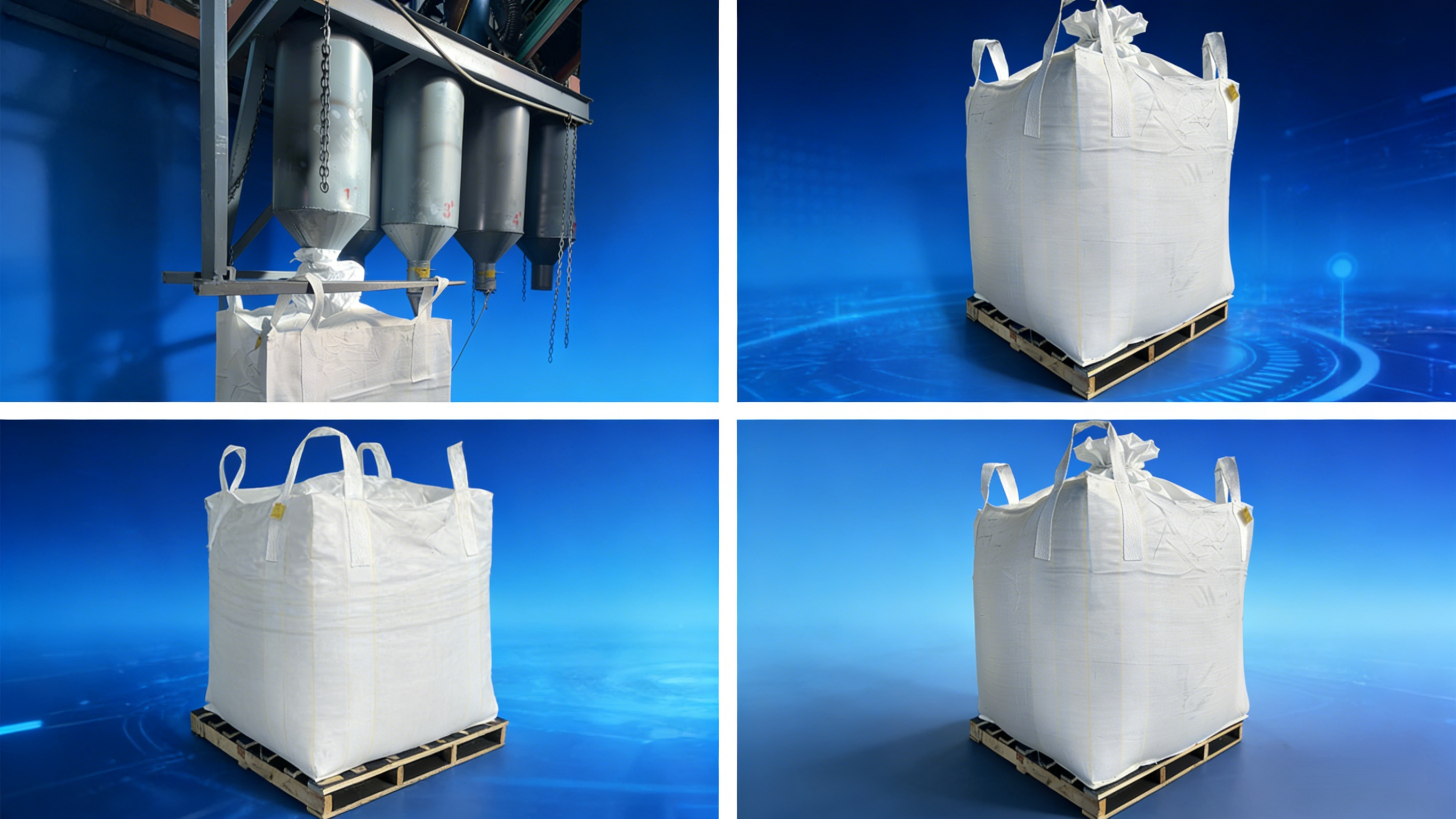

四、包装规格

产品采用双层密封防潮包装,内层为0.10mm厚食品级聚乙烯(PE)薄膜袋,具备优异的防潮性,防止粉末吸潮结块;外层为80-100g/㎡高强度聚丙烯编织袋或进口牛皮纸袋,抗撕裂强度≥25N,能承受搬运与运输过程中的外力冲击。

常规包装规格:小批量试用装为1kg/袋、5kg/袋,配备密封拉链,便于多次取用;标准工业包装为25kg/袋,袋身尺寸50cm×80cm,内置加强提手,便于人工搬运;大批量采购可提供500kg/吨包(颗粒炭),采用集装袋包装,配备吊装环,适配叉车装卸。所有包装均清晰标注产品名称、型号、粒径、碘吸附值、生产日期、批号及质量等级,食品级与工业级产品采用颜色标识区分(食品级为绿色标识带,工业级为灰色标识带),避免混用。密封状态下,储存于阴凉干燥环境,保质期为2年,开封后需密封保存并在30天内使用完毕。

五、注意事项

1. 储存规范:应存放于专用干燥仓库,仓库温度控制在5-35℃,相对湿度≤60%,避免阳光直射及靠近高温热源(如蒸汽管道、加热炉)。仓库需配备防潮通风设备,产品应放置在木质托盘或塑料托盘上,与地面、墙面保持10cm以上距离,防止潮气侵入。严禁与强酸、强碱、有毒气体及易挥发化学品混合储存,各类物资储存间隔不小于5米,防止交叉污染导致产品吸附性能失效。

2. 运输要求:运输车辆需保持干燥清洁,车厢内铺设防雨布及防潮垫层。装卸过程中必须轻装轻卸,严禁使用铁钩等尖锐工具拖拽包装,避免包装破损导致颗粒泄漏。运输途中需做好防雨、防晒、防尘措施,不得与石块、钢材等坚硬物品及液体货物混合装载。长途运输时,需定期检查包装完整性,发现破损应及时采取密封措施,运输车辆应配备相应的防火设施。

3. 使用操作:装填吸附设备前,需用清水冲洗1-2次,去除表面粉尘,冲洗废水需收集处理,避免污染环境。水处理系统中,活性炭滤层高度建议为1.5-2.0米,滤速控制在8-12m/h,确保处理效果。使用过程中需定期检测进出水(气)污染物浓度,当吸附效率降至初始值的50%以下时,需进行再生或更换,再生采用高温蒸汽脱附法,再生时间为8-10小时。

4. 安全警示:产品燃点为450-500℃,属于不易燃物质,但在密闭空间内大量堆积且通风不良时,吸附过程中释放的微量热量可能积聚,因此储存及使用区域需严禁明火,配备干粉灭火器等消防设施,消防器材每月检查确保有效。操作人员装填时需佩戴防尘口罩、防护眼镜及乳胶手套,避免颗粒吸入呼吸道及接触皮肤。废弃的吸附饱和炭需交由专业环保机构处理,不得随意倾倒,避免造成二次污染。

Guokr Activated Carbon Product Introduction: Guokr Activated Carbon is a porous adsorbent material produced from premium nut shells including walnut, apricot, and jujube shells. Through processes such as screening, low-temperature carbonization (500-700°C), high-temperature activation (800-1000°C), and purification, the shells are transformed into a material with a naturally dense wood-like structure. The specially processed shells develop a highly developed microporous system, offering advantages like high adsorption capacity, strength, and easy regeneration. Widely used in drinking water purification, food processing, and precious metal extraction, it stands as the optimal adsorbent material that balances cost-effectiveness and performance.

Appearance Characteristics: The product appears as irregular black granules, with slight variations in shape depending on the raw material. Walnut shell-based products have fuller granules, while apricot shell-based products have slightly sharper edges, with no obvious edges overall. Common particle sizes cover 6-12 mesh, 12-24 mesh, and 24-48 mesh, where 12-24 mesh is the general specification, and 24-48 mesh is suitable for fine purification scenarios. The surface of the granules is rough and porous, with a dry and non-greasy feel, and fine pores can be seen under strong light. The bulk density is 0.48-0.60g/cm³, between that of coconut shell activated carbon (0.42-0.50g/cm³) and coal-based activated carbon (0.55-0.75g/cm³). High-quality products have a particle integrity of ≥96%, with a wear rate of ≤2.5% after mechanical vibration testing. They maintain good initial buoyancy when soaked in water, and slowly settle after adsorption saturation, without significant pulverization.

Core Characteristics 1. Balanced Adsorption Performance: With a BET specific surface area of 900-1300 m²/g, the material features 75%-85% micropores (1-2 nm) and 10%-20% mesopores (2-50 nm), creating an optimal pore structure for adsorbing small molecular pollutants and select medium/large molecules. Key performance metrics demonstrate exceptional results: iodine adsorption capacity of 850-1100 mg/g, methylene blue adsorption of 120-180 mg/g, and phenol adsorption ≥35 mg/g. In drinking water purification, it achieves over 99.5% residual chlorine removal efficiency, with organic adsorption rates 20%-30% higher than coal-based activated carbon.

Robust Mechanical Strength: With a mechanical strength of ≥94% (reaching 96% for walnut shell-based products), it withstands dynamic conditions like water treatment backwashing and fluidized bed adsorption. During backwashing in water treatment plants (10-15L/(m²·s) intensity), the breakage rate remains below 1%, minimizing carbon powder's impact on effluent quality. Its exceptional wear resistance ensures low carbon consumption during prolonged use, significantly reducing operational costs.

Chemically stable: The product maintains a pH range of 6.0-9.0, neutral in nature, without altering the acidity or alkalinity of the treatment medium. With sulfur content ≤0.2% and nitrogen content ≤1.0%, it exhibits strong chemical inertness, showing no reaction with common organic compounds or heavy metal ions in water. The food-grade product strictly complies with GB/T 12496-2015 standards, featuring ultra-low heavy metal levels (arsenic ≤5mg/kg, lead ≤20mg/kg, mercury ≤0.1mg/kg), meeting all food safety requirements.

Excellent regenerability: Utilizing high-temperature steam regeneration (350-450°C), the adsorption capacity can recover to 80%-85% of its initial value. The regeneration cycle is one-third of the adsorption cycle, allowing 5-8 regeneration cycles. Compared to coconut shell activated carbon, this method reduces energy consumption by 15%-20%, offering superior overall operational costs, making it particularly suitable for large-scale continuous systems.

III. Application Fields 1. Drinking Water Purification: In advanced treatment systems for water treatment plants, 12-24 mesh fruit shell activated carbon-filled filters effectively remove residual chlorine, odors, halogenated hydrocarbons, and trace pesticide residues. The treated water contains ≤0.05mg/L of residual chlorine and has odor levels below the 20 odor threshold units, meeting the GB 5749-2022 Drinking Water Hygiene Standard. For household water purifiers, 24-48 mesh fine-grained carbon serves as the core filter material, with a single cartridge capable of processing 2-5m³ of water, ensuring safe drinking water for families.

Food and Beverage Industry: In the sugar industry, this process is used for decolorization and purification of sucrose and fructose syrup. A dosage of 0.2%-0.4% effectively removes caramel pigments and melanoidin from sugar solutions, elevating product whiteness to over 92%. In alcoholic beverage production, it clarifies yellow rice wine and fruit wines by adsorbing aldehydes and ester impurities, resulting in a purer taste and extending shelf life by 6-12 months. In the beverage sector, it neutralizes astringency in fruit juices and removes impurities from tea beverages, eliminating tannic acid and bitter compounds while preserving original flavors and nutritional components.

Precious Metals Extraction: In heap leaching and carbon slurry extraction processes for gold, silver and other precious metals, 6-12 mesh fruit shell activated carbon demonstrates high efficiency in adsorbing gold cyanide complexes and silver cyanide complexes from cyanide leaching solutions. The adsorption capacities reach 350-500g/t for gold and 800-1200g/t for silver, with a desorption efficiency of ≥97%. This technology is particularly suitable for extracting medium-to-low grade gold and silver ores, and has been widely adopted in mining regions such as Henan and Shandong.

Industrial Wastewater Treatment: In chemical wastewater treatment, it effectively removes organic pollutants such as benzene, toluene, and phenols, achieving a COD removal rate of 35%-55%. For dyeing wastewater, it decolorizes reactive and acid dyes with 80%-90% efficiency. In electroplating wastewater treatment, it adsorbs and removes heavy metal ions (e.g., chromium, nickel, copper) at over 90%, serving as a key advanced treatment unit to ensure compliance with discharge standards.

Gas-phase purification applications: In industrial exhaust treatment, it effectively adsorbs VOCs emitted by coating and printing industries, achieving 80%-90% efficiency for benzene and ethyl acetate. As a core material in activated carbon packs and air purifier filters, it removes 70-120mg/g of formaldehyde and TVOCs, significantly improving indoor air quality. Additionally, it serves as a filter cartridge in gas masks to neutralize toxic gases, ensuring worker safety.

Packaging Specifications The product features a double-layer moisture-proof packaging system. The inner layer consists of 0.10mm-thick food-grade polyethylene (PE) film bags with superior moisture resistance, preventing powder from absorbing moisture and clumping. The outer layer is made of 80-100g/m² high-strength polypropylene woven bags or imported kraft paper bags, with a tear strength of ≥25N, capable of withstanding external impacts during handling and transportation.

Standard packaging specifications: Small-batch trial packs are available in 1kg/5kg bags with sealed zippers for easy refilling, while standard industrial packaging comes in 25kg/50cm×80cm bags featuring reinforced handles for manual handling. Bulk purchases can be provided in 500kg/ton bags (granular charcoal) with containerized packaging and lifting rings for forklift loading. All packaging clearly displays product name, model, particle size, iodine adsorption value, production date, batch number, and quality grade. Food-grade and industrial-grade products are distinguished by color labels (food-grade with green bands, industrial-grade with gray bands) to prevent confusion. Store in a cool, dry place when sealed. The shelf life is 2 years, and opened products must be resealed and used within 30 days.

Precautions 1. Storage Guidelines: Store in a dedicated dry warehouse maintained at 5-35°C with relative humidity ≤60%, avoiding direct sunlight and proximity to high-temperature sources (e.g., steam pipes, heating furnaces). The warehouse must be equipped with moisture-proof ventilation systems. Place products on wooden or plastic pallets at least 10cm above the floor/walls to prevent moisture ingress. Strictly prohibit mixing with strong acids, strong alkalis, toxic gases, or volatile chemicals. Maintain a minimum 5-meter separation between all materials to prevent cross-contamination that may impair product adsorption performance.

Transportation Requirements: Transport vehicles must be kept dry and clean, with rainproof fabric and moisture-proof padding installed in the cargo compartment. Handling procedures must be performed gently, and the use of sharp tools like iron hooks to drag packages is strictly prohibited to prevent packaging damage and particle leakage. During transit, measures must be taken to protect against rain, sunlight, and dust, and the vehicles must not be loaded with hard materials such as stones or steel, nor mixed with liquid cargo. For long-distance transportation, the packaging integrity must be regularly inspected, and any damage found must be promptly sealed. The transport vehicles must also be equipped with appropriate fire prevention facilities.

Operating Procedures: Before loading the adsorption equipment, rinse the surface 1-2 times with clean water to remove dust. Collect and treat the rinse wastewater to prevent environmental contamination. In the water treatment system, the activated carbon filter layer should be 1.5-2.0 meters high, with a filtration rate maintained at 8-12 m/h to ensure effective treatment. Regularly monitor pollutant concentrations in both influent and effluent (gas) during operation. When the adsorption efficiency drops below 50% of the initial value, regeneration or replacement is required. The regeneration process uses high-temperature steam desorption, lasting 8-10 hours.

Safety Warning: The product has a flammability range of 450-500°C and is classified as non-flammable. However, in enclosed spaces with poor ventilation where large quantities are stored, trace heat released during adsorption may accumulate. Therefore, open flames must be strictly prohibited in storage and usage areas. Fire-fighting equipment such as dry powder fire extinguishers must be provided, and fire safety equipment should be inspected monthly to ensure effectiveness. Operators must wear dust masks, protective goggles, and latex gloves during loading to prevent particle inhalation and skin contact. Spent adsorption saturated carbon must be disposed of by professional environmental agencies and must not be dumped indiscriminately to avoid secondary pollution.