天源椰壳黄金炭产品介绍

天源椰壳黄金炭是专为贵金属提取领域研发的特种吸附材料,以东南亚优质椰子壳为原料,经精准炭化(650-850℃)、高温蒸汽活化(900-1050℃)、分级筛选及表面改性处理制成。其核心优势在于发达的微孔结构、优异的金吸附选择性及高效解吸性能,适配黄金堆浸、炭浆法(CIP)、炭浸法(CIL)等主流提金工艺,能从氰化浸出液中高效富集金元素,是黄金选矿行业的核心耗材。

一、外观特征

产品呈黑色不规则颗粒状,颗粒形态饱满圆润,无尖锐棱角,避免在搅拌过程中磨损设备内壁。常规粒径规格集中于4-8目、8-12目、12-20目,其中8-12目为炭浆法工艺首选,4-8目适用于堆浸场喷淋系统。颗粒表面粗糙多孔,触感干涩无油腻感,经放大镜观察可见细密孔隙开口。堆积密度为0.42-0.50g/cm³,低于煤质黄金炭,相同体积下比表面积更大。优质产品颗粒完整性≥98%,经球磨测试后磨损率≤2%,在水中浸泡24小时后无明显溶胀、不溃散,沥干后颗粒形态保持完好。

二、核心特性

1. 金吸附性能卓越:BET比表面积达1000-1500m²/g,微孔(1-3nm)占比超90%,该孔径与金氰络离子([Au(CN)₂]⁻)直径高度匹配,吸附位点密度达1.2×10²¹个/g。静态金吸附容量≥500g/t,动态吸附速率达0.8g/(t·h),在氰化浸出液(金浓度0.5-5g/m³)中,吸附率超99%,远高于煤质黄金炭(吸附率95%-97%)。

2. 选择性吸附能力强:对金氰络离子的选择性系数(相对于铜、铁等杂质离子)≥1000,在含铜、铁、锌等干扰离子的浸出液中,仍能优先吸附金元素,减少杂质离子对后续解吸的影响。对银、钯等贵金属也有一定吸附能力,可实现多金属综合回收。

3. 机械强度与耐磨性优异:机械强度≥96%,抗压强度≥12MPa,能耐受炭浆法工艺中搅拌桨的高速冲击(搅拌速度200-300r/min)及输送泵的剪切作用,炭粉损耗率控制在0.1%/天以内,降低选矿成本。

4. 解吸性能高效稳定:表面改性处理减少了不可逆吸附位点,采用高温氰化钠解吸工艺(120-150℃、0.15MPa),金解吸率≥98%,解吸时间缩短至4-6小时,解吸后炭体残留金量≤5g/t,可直接循环使用,再生次数达8-12次。

三、应用领域

1. 炭浆法(CIP)提金工艺:在金矿选矿厂CIP系统中,8-12目椰壳黄金炭填充于吸附塔,与含金氰化矿浆逆流接触,金吸附率稳定在99.2%以上。云南某大型金矿应用表明,使用该产品后,金总回收率提升2.3个百分点,吨矿金回收成本降低12元。适用于处理金品位5-30g/t的原生金矿及氧化金矿。

2. 炭浸法(CIL)提金工艺:在浸出与吸附同步进行的CIL系统中,4-8目颗粒炭能随矿浆流动,实时吸附浸出的金氰络离子,缩短工艺流程。在新疆某氧化金矿应用中,浸出-吸附周期从传统工艺的24小时缩短至18小时,金浸出吸附率达99.5%。

3. 堆浸法提金工艺:用于低品位金矿(金品位0.5-5g/t)堆浸场,4-8目粗颗粒炭填充于吸附柱,处理含金沙淋洗液,金吸附率达98.8%以上。内蒙古某堆浸矿山使用后,淋洗液中金浓度从初始3g/m³降至0.005g/m³以下,实现资源高效回收。

4. 贵金属回收辅助:在电子垃圾贵金属回收中,用于吸附电路板浸出液中的金、银,金吸附容量达800g/t,银吸附容量达1200g/t,为二次资源回收提供高效方案。在电镀废液处理中,可吸附残留金离子,使废液中金浓度低于0.1mg/L,符合GB 21900-2008排放标准。

指标基本参数(可按客户需求定制):

型号 | 指标(可定制) | 用途 |

TY-YKL3(椰壳颗粒炭) | 粒度:3-12目 | 炭浆法和堆浸法提炼黄金专用椰壳炭 |

TY-YKL10(椰壳颗粒炭) | 粒度:10-24目 | 用于电厂水、锅炉水、凝结水、反渗透系统、 |

TYK-YKL20(椰壳颗粒炭) | 粒度:20-48目 | 净水器滤芯、自来水厂、饮料、酒类、食品、高纯水应用 |

TY-YKF200(椰壳粉末炭) | 粒度:150-325目 | 饮用水处理、贵金属提炼、污水处理 |

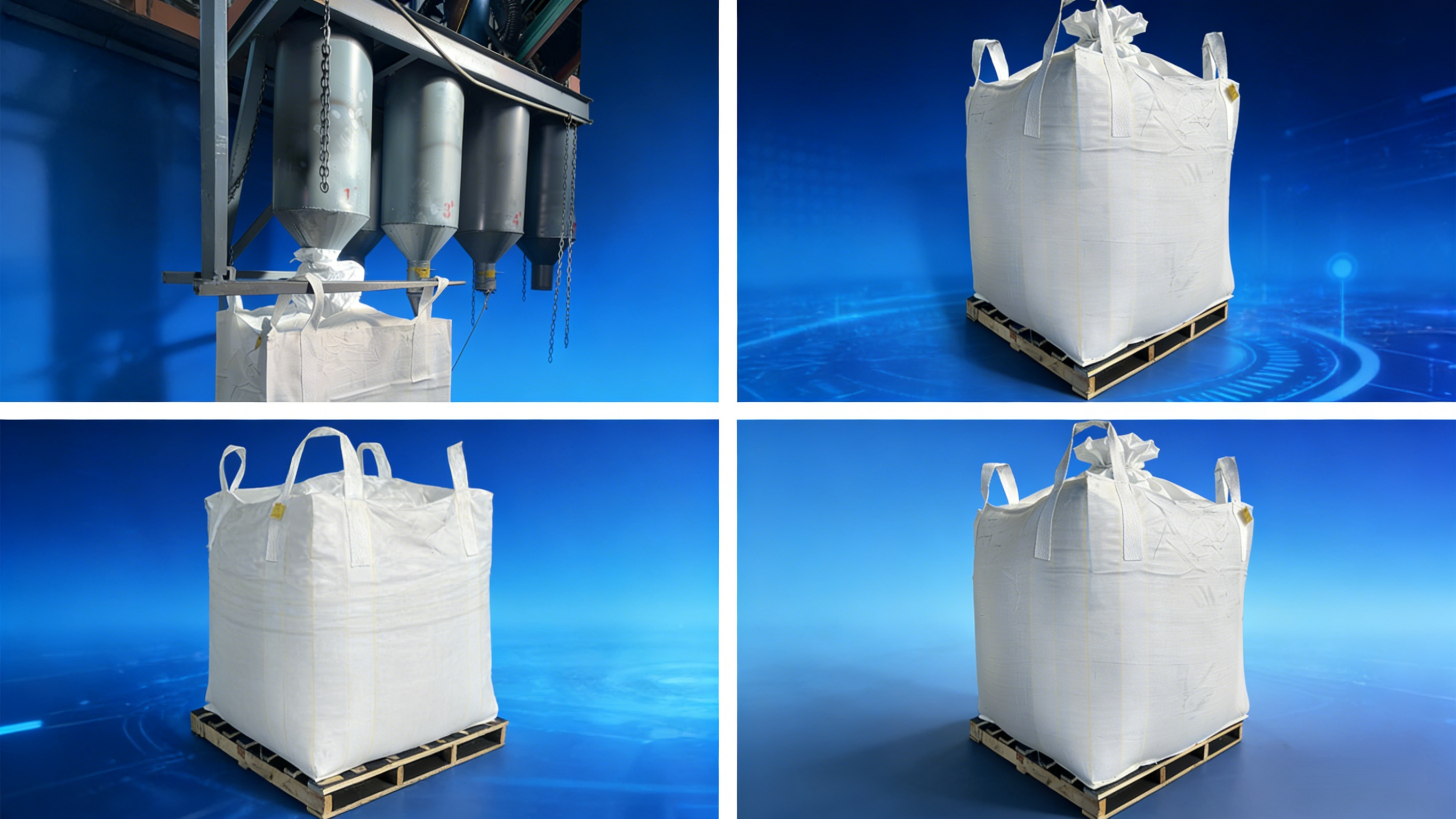

四、包装规格

采用定制化防污染密封包装,内层为0.12mm厚食品级PE薄膜袋,具备极佳的防潮性与抗化学腐蚀性,防止吸附空气中水分及杂质;中层为铝塑复合膜,隔绝氧气与光线,延缓炭体氧化;外层为100g/㎡高强度聚丙烯编织袋,配备内置加强筋,抗撕裂强度≥30N。

常规包装规格:标准工业装为25kg/袋,袋身尺寸50cm×80cm,印有清晰的产品标识(含粒径、金吸附容量、批号等信息)及“贵金属专用”警示语;大型选矿厂可定制1000kg/吨包,采用集装袋包装,配备吊装环及卸料口,适配自动化投料系统。包装颜色统一为深灰色,与普通椰壳活性炭区分,避免混用。密封状态下,储存于阴凉干燥环境,保质期为2年,开封后需在30天内使用完毕,并做好密封防潮。

五、注意事项

1. 储存规范:专用仓库需保持干燥通风,温度控制在5-35℃,相对湿度≤55%,地面铺设防潮垫层,产品放置于木质托盘上,与地面、墙面间距≥20cm。严禁与酸、碱、氧化剂及含硫化合物混存,储存区域需远离氰化物储存区(间隔≥15米),防止提前吸附杂质离子导致性能失效。

2. 运输要求:运输车辆需经过清洁消毒,车厢内铺设防雨布及耐腐蚀垫层。装卸时轻装轻卸,严禁使用铁钩拖拽包装,避免剧烈震动导致颗粒破碎。运输途中做好防雨、防晒措施,不得与液体化学品、尖锐硬物混装。长途运输每300公里检查一次包装完整性,发现破损立即更换密封包装,运输车辆需配备应急防护用品。

3. 使用操作:装填吸附塔前,需用清水冲洗1-2次,去除表面粉尘,冲洗水需收集处理,避免金流失。CIP系统中,炭浆浓度需控制在5-8g/L,搅拌速度不宜超过300r/min,防止炭体过度磨损。定期检测吸附后液金浓度,当浓度超过0.02g/m³时,需及时补充新炭。解吸时严格控制温度与压力,避免温度过高导致炭体烧损。

4. 安全警示:产品燃点≥480℃,储存及使用区域严禁明火,每50㎡配备2具4kg干粉灭火器,每月检查消防设施。操作人员需经过专业培训,佩戴防毒口罩、耐酸碱手套及防护眼镜,避免接触氰化矿浆。废弃饱和炭需交由有资质的贵金属回收企业处理,不可随意丢弃,解吸废液需符合环保标准后排放。

Coconut Shell Gold Carbon Product Introduction: This specialized adsorbent material, developed for precious metal extraction, is manufactured from premium Southeast Asian coconut shells through a precision carbonization process (650-850°C), high-temperature steam activation (900-1050°C), graded screening, and surface modification. Its core advantages include a well-developed microporous structure, exceptional gold adsorption selectivity, and high-efficiency desorption performance. The material is compatible with mainstream gold extraction processes such as heap leaching, carbon pulp method (CIP), and carbon impregnation method (CIL), enabling efficient gold enrichment from cyanide leaching solutions. As a core consumable in the gold mineral processing industry, it serves as a vital component in gold ore processing.

Appearance Characteristics: The product appears as irregular black granules, with full and rounded shapes without sharp edges to avoid damaging the inner walls of equipment during mixing. Common particle sizes are concentrated in 4-8 mesh, 8-12 mesh, and 12-20 mesh, where 8-12 mesh is the preferred choice for the carbon slurry process, and 4-8 mesh is suitable for the spray system in heap leaching fields. The surface of the granules is rough and porous, with a dry and non-greasy texture. Under a magnifying glass, fine pores can be observed. The bulk density is 0.42-0.50g/cm³, lower than that of premium coal, but it has a larger specific surface area per unit volume. High-quality products have a particle integrity of ≥98%, with a wear rate of ≤2% after ball milling tests. After soaking in water for 24 hours, there is no significant swelling or disintegration, and the granules maintain their shape after draining.

Core Characteristics 1. Superior Gold Adsorption Performance: With a BET specific surface area of 1000-1500 m²/g and over 90% micropores (1-3 nm), the pore size perfectly matches the diameter of gold cyanide ions ([Au(CN)₂]⁻), achieving a site density of 1.2×10²¹ sites/g. The static adsorption capacity exceeds 500 g/t, with a dynamic adsorption rate of 0.8 g/(t·h). In cyanide leaching solutions (gold concentration 0.5-5 g/m³), the adsorption rate surpasses 99%, significantly outperforming coal-based gold carbon (95%-97%).

Superior selective adsorption: The gold-cyanate complex demonstrates a selectivity coefficient (relative to impurity ions like copper and iron) of ≥1000, enabling preferential gold adsorption in leaching solutions containing copper, iron, zinc, and other interfering ions, thereby minimizing the impact of impurities on subsequent desorption. It also exhibits adsorption capacity for precious metals such as silver and palladium, facilitating comprehensive recovery of multiple metals.

Superior mechanical strength and wear resistance: Mechanical strength ≥96%, compressive strength ≥12MPa, capable of withstanding high-speed impact from the mixing paddle (200-300r/min) and shear forces from the conveying pump in the carbon slurry process. The carbon powder loss rate is controlled within 0.1% per day, significantly reducing mineral processing costs.

Efficient and stable desorption performance: Surface modification reduces the irreversible adsorption sites, and the high temperature sodium cyanide desorption process (120-150℃,0.15MPa) is adopted. The gold desorption rate is ≥98%, the desorption time is shortened to 4-6 hours, and the residual gold content of the carbon body after desorption is less than 5g/t. It can be recycled directly, and the regeneration times are up to 8-12 times.

Application Fields 1. Carbon Slurry Process (CIP) for Gold Recovery: In the CIP system of a gold ore dressing plant, 8-12 mesh coconut shell gold carbon is packed in the adsorption tower and counter-currently contacted with gold-bearing cyanide ore slurry, achieving a stable gold adsorption rate above 99.2%. A large-scale gold mine in Yunnan Province demonstrated that the use of this product increased the total gold recovery rate by 2.3 percentage points and reduced the gold recovery cost per ton of ore by 12 yuan. It is suitable for processing primary gold ores and oxidized gold ores with gold grades ranging from 5 to 30 g/t.

Carbon Immersion (CIL) Gold Extraction Process: In the CIL system where leaching and adsorption occur simultaneously, 4-8 mesh granular carbon can flow with the ore pulp to adsorb leached gold cyanide ions in real time, thereby shortening the process flow. In a gold oxide mine application in Xinjiang, the leaching-adsorption cycle was reduced from 24 hours in traditional methods to 18 hours, achieving a gold leaching and adsorption rate of 99.5%.

Pile leaching gold extraction process: This method is applied to low-grade gold ore (gold grade 0.5-5g/t) pile leaching fields. Coarse particles (4-8 mesh) are packed into adsorption columns to treat gold-containing leaching solutions, achieving a gold adsorption rate of over 98.8%. At a pile leaching mine in Inner Mongolia, the gold concentration in the leaching solution was reduced from an initial 3g/m³ to below 0.005g/m³, enabling efficient resource recovery.

Precious Metal Recovery Support: In e-waste precious metal recovery, it adsorbs gold and silver from circuit board leachate, with gold adsorption capacity reaching 800g/t and silver adsorption capacity reaching 1200g/t, providing an efficient solution for secondary resource recovery. In electroplating wastewater treatment, it can adsorb residual gold ions, reducing the gold concentration in wastewater to below 0.1mg/L, meeting the discharge standards of GB 21900-2008.

Packaging Specifications: Customized anti-contamination sealed packaging with three-layer structure. The innermost layer is a 0.12mm-thick food-grade PE film bag, featuring superior moisture-proofing and chemical resistance to prevent air moisture and impurities absorption. The middle layer consists of aluminum-plastic composite film that isolates oxygen and light to delay carbon oxidation. The outermost layer is a 100g/m² high-strength polypropylene woven bag with built-in reinforcing ribs, providing a tear resistance of ≥30N.

Standard packaging specifications: The standard industrial package weighs 25kg per bag, with dimensions of 50cm×80cm. It features clear product labels (including particle size, gold adsorption capacity, batch number, etc.) and a "Precious Metals Only" warning. Large-scale mineral processing plants can customize 1000kg/ton bags, which are containerized with lifting rings and discharge ports for seamless integration with automated feeding systems. The packaging is uniformly dark gray to distinguish it from regular coconut shell activated carbon and prevent confusion. When sealed, store in a cool, dry environment. The product has a shelf life of 2 years. Once opened, use within 30 days and ensure proper sealing to prevent moisture.

Storage Guidelines 1. Storage Specifications: The dedicated warehouse shall maintain dryness and ventilation, with temperature controlled between 5-35°C and relative humidity ≤55%. Moisture-proof mats shall be installed on the floor, and products shall be placed on wooden pallets at a minimum 20cm clearance from both floor and walls. Mixing with acids, alkalis, oxidizers, or sulfur-containing compounds is strictly prohibited. The storage area must be kept at least 15 meters away from cyanide storage zones to prevent premature adsorption of impurity ions that may degrade product performance.

Transportation Requirements: Transport vehicles must undergo thorough cleaning and disinfection, with rainproof fabric and corrosion-resistant padding installed in the cargo compartment. Handle loading/unloading with care, strictly prohibiting the use of iron hooks to drag packages to prevent particle breakage from violent vibrations. Implement rain and sun protection measures during transit, and avoid mixing with liquid chemicals or sharp objects. For long-distance transport, inspect packaging integrity every 300 kilometers. Replace any damaged packaging immediately and ensure vehicles are equipped with emergency protective gear.

Operating Procedures: Before loading the adsorption tower, rinse the surface 1-2 times with clean water to remove dust. Collect and treat the rinse water to prevent gold loss. In the CIP system, maintain the carbon slurry concentration at 5-8g/L and keep the stirring speed below 300 rpm to prevent excessive wear. Regularly monitor the gold concentration in the post-adsorption liquid. Replace the carbon promptly when the concentration exceeds 0.02g/m³. During desorption, strictly control temperature and pressure to avoid carbon burnout caused by overheating.

Safety Warning: The product has a combustion point of ≥480°C. Open flames are strictly prohibited in storage and usage areas. Two 4kg dry powder fire extinguishers must be provided for every 50㎡, with monthly inspections of fire safety equipment. Operators must undergo professional training and wear gas masks, acid/alkali-resistant gloves, and protective goggles to avoid contact with cyanide-containing mineral slurry. Spent saturated carbon must be disposed of by qualified precious metal recycling enterprises and not discarded indiscriminately. Desorption waste liquid must meet environmental standards before discharge.