天源蜂窝活性炭产品介绍

天源蜂窝活性炭是一种经特殊成型工艺制成的规则多孔结构吸附材料,以优质煤质活性炭粉、木质活性炭粉为基材,辅以专用粘结剂,经混料、挤压成型、低温干燥、高温活化等工序加工而成。其独特的蜂窝状通孔结构大幅降低了流体阻力,兼具吸附效率高、使用寿命长、更换便捷等优势,在工业废气净化、室内空气治理、污水处理等领域应用广泛,尤其适用于大风量、低浓度污染物处理场景。

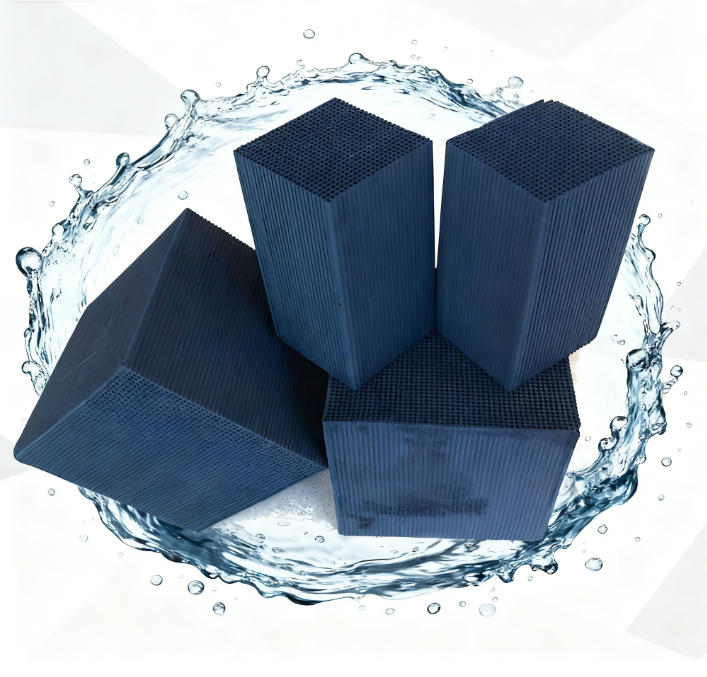

一、外观特征

产品呈黑色规则蜂窝状块体,常见外形为正方形或长方形,标准规格包括100mm×100mm×100mm、100mm×100mm×50mm、200mm×200mm×100mm等,可根据设备尺寸定制异形规格。蜂窝孔道呈正六边形均匀分布,孔径规格分为1.5mm、2.0mm、3.0mm三类,其中2.0mm孔径在废气处理中应用最广。产品表面平整光滑,无明显裂纹、缺角及毛刺,孔道通畅无堵塞,断面结构均匀致密。堆积密度为0.60-0.75g/cm³,手感坚实,单块抗压强度优异,垂直于孔道方向抗压强度≥0.8MPa,平行方向≥0.5MPa,不易碎裂。

二、核心特性

1. 传质效率高:蜂窝状通孔结构使流体(气/液)通过阻力大幅降低,风阻损失≤50Pa/m,远低于颗粒活性炭(风阻损失≥200Pa/m),可减少风机能耗30%以上。孔道比表面积利用率达90%,流体与炭体接触充分,吸附速率较颗粒炭提升50%-70%,15-25分钟即可达到吸附平衡。

2. 吸附性能稳定:BET比表面积为600-1000m²/g,中孔(2-50nm)占比40%-60%,适配VOCs、硫化物等中大分子污染物吸附,碘吸附值≥700mg/g,苯吸附量≥200mg/g,在25℃、相对湿度50%条件下,对甲醛吸附量达60-100mg/g。

3. 结构稳定性强:采用高温活化工艺(800-950℃)增强炭体与粘结剂结合力,产品吸水率≤5%,在高湿度环境中无溶胀、不变形。耐磨强度≥95%,长期运行中无炭粉脱落,避免造成二次污染,使用寿命可达6-12个月,是颗粒活性炭的2-3倍。

4. 安装维护便捷:规则块状结构便于标准化安装,可直接拼接填充于吸附设备,无需专用固定装置,安装效率提升40%。更换时整体拆卸,操作简单,减少停机时间,降低维护成本。

三、应用领域

1. 工业废气净化:在涂装、印刷、电子、化工等行业VOCs处理中,采用2.0mm孔径蜂窝炭填充吸附塔,对苯、甲苯、乙酸乙酯等污染物吸附效率达85%-95%,处理后废气符合GB 37822-2019排放标准。家具厂喷漆废气处理中,单台设备可处理风量10000-50000m³/h,VOCs去除量达10-50kg/天。

2. 烟气脱硫脱硝:燃煤电厂、垃圾焚烧厂烟气处理中,蜂窝活性炭作为吸附-催化载体,可同时吸附SO₂和NOₓ,SO₂吸附容量达60-100mg/g,脱硝效率35%-55%,吸附的SO₂可转化为硫酸铵副产品,实现资源回收。

3. 室内空气治理:作为空气净化器、新风系统核心滤材,1.5mm孔径产品对甲醛、TVOC等室内污染物吸附效率达80%以上,适配家用及商用净化设备。新装修房屋空气治理中,每10㎡空间放置1块100mm×100mm×100mm蜂窝炭,可在7-15天内将甲醛浓度降至0.1mg/m³以下,符合GB 50325-2020标准。

4. 水处理领域:在饮用水深度处理中,用于去除异味、余氯及微量有机物,处理水量达5-20m³/(m³·d),余氯去除率≥99%。工业废水脱色处理中,对印染废水脱色率达80%-90%,降低废水COD值30%-50%,常作为生物处理后的深度处理单元。

5. 其他应用:汽车尾气净化中,作为催化剂载体负载贵金属,提升尾气中CO、NOₓ转化效率;地下车库通风系统中,吸附汽车尾气中的烃类污染物,改善车库空气质量;冷库保鲜中,吸附果蔬释放的乙烯气体,延长保鲜期2-3倍。

四、包装规格

采用防潮防损包装方案,单块产品先用PE薄膜独立封装,防止运输中摩擦损伤;多块组合包装时,内层用气泡膜分隔缓冲,外层采用五层瓦楞纸箱,箱内填充珍珠棉固定,避免颠簸导致碎裂。

常规包装规格:标准小包装为10块/箱(100mm×100mm×100mm规格,毛重约7.5kg),箱身印有产品型号、孔径、比表面积等信息;工业大批量包装为50块/箱或定制托盘包装(每托盘装载200-500块),托盘采用缠绕膜加固,适配叉车装卸。包装外标注“防潮、轻放、勿压”警示标识,工业级与民用级产品通过箱身颜色区分(工业级为灰色,民用级为蓝色)。密封状态下,阴凉干燥环境储存保质期为2年,开封后需密封保存并在60天内使用。

五、注意事项

1. 储存规范:存放于专用干燥仓库,温度控制在0-40℃,相对湿度≤65%,仓库需配备通风防潮设备,避免阳光直射及靠近高温热源(如蒸汽管道、加热设备)。产品应整齐堆叠在木质托盘上,堆叠高度不超过1.5米,防止底层产品受压破损,与地面、墙面间距≥15cm,隔绝潮气。严禁与酸、碱、氧化剂及易挥发化学品混存,储存间隔≥8米,防止交叉污染。

2. 运输要求:运输车辆需保持干燥清洁,车厢内铺设防雨布及防潮垫层。装卸时轻拿轻放,严禁抛掷、挤压,采用人工或叉车平稳搬运,叉车作业时需避免货叉撞击包装。运输途中做好防雨、防晒、防尘措施,不得与液体货物、尖锐硬物混装。长途运输每200公里检查一次包装完整性,发现破损及时加固,运输车辆需配备应急防护用品。

3. 使用操作:安装前需检查产品外观,剔除缺角、裂纹产品,安装时确保孔道方向与流体流向一致,避免装反影响吸附效果。废气处理系统中,需定期检测进出口污染物浓度,当吸附效率降至初始值的40%以下时,需进行再生或更换,再生采用300-400℃高温蒸汽脱附,再生时间为6-8小时。水洗再生仅适用于水溶性污染物,水洗后需烘干再投入使用。

4. 安全警示:产品燃点为450-500℃,储存及使用区域严禁明火,每100㎡配备2具4kg干粉灭火器,每月检查消防设施有效性。吸附VOCs等易燃污染物后,饱和炭需远离火源,再生时需控制升温速率(≤5℃/min),防止局部过热引发燃烧。废弃饱和炭需交由有资质的环保机构处置,不可随意倾倒,避免造成土壤或水源污染。操作人员安装时佩戴防尘口罩及手套,避免吸入少量炭粉。

Product Introduction: Tianyuan Honeycomb Activated Carbon Tianyuan Honeycomb Activated Carbon is a specialized porous adsorption material manufactured through a unique molding process. Using premium coal-based and wood-based activated carbon powders as base materials, it is compounded with specialized binders and processed through mixing, extrusion molding, low-temperature drying, and high-temperature activation. The distinctive honeycomb structure significantly reduces fluid resistance while delivering high adsorption efficiency, extended service life, and easy replacement. Widely applied in industrial exhaust purification, indoor air treatment, and wastewater treatment, it is particularly effective for handling high-volume, low-concentration pollutants.

Appearance Characteristics: The product appears as a black, regular honeycomb block, commonly in square or rectangular shapes. Standard sizes include 100mm×100mm×100mm, 100mm×100mm×50mm, and 200mm×200mm×100mm, with custom shapes available based on equipment dimensions. The honeycomb channels are evenly distributed in a regular hexagon pattern, with hole diameters categorized into three 1.5mm, 2.0mm, 3.0mm classes, among which the 2.0mm diameter is the most widely used in exhaust gas treatment. The surface of the product is smooth and flat, without obvious cracks, missing corners, or burrs. The channels are unobstructed and the cross-sectional structure is uniform and dense. The bulk density is 0.60-0.75g/cm³, giving it a firm feel. Each unit has excellent compressive strength, with a minimum compressive strength of 0.8MPa perpendicular to the channel direction and 0.5MPa parallel to the channel direction, making it resistant to cracking.

Core Features 1. High Mass Transfer Efficiency: The honeycomb perforated structure dramatically reduces fluid (gas/liquid) flow resistance, with wind resistance loss ≤50Pa/m – significantly lower than granular activated carbon (≥200Pa/m). This design cuts fan energy consumption by over 30%. With 90% channel surface area utilization, the fluid achieves full contact with the carbon matrix, delivering 50%-70% faster adsorption than granular carbon. Adsorption equilibrium is reached within 15-25 minutes.

Stable adsorption performance: With a BET specific surface area of 600-1000m²/g and mesoporous (2-50nm) pores accounting for 40%-60%, it effectively adsorbs medium-to-large molecular pollutants including VOCs and sulfides. The adsorption capacity for iodine is ≥700mg/g, and for benzene, it reaches ≥200mg/g. Under conditions of 25℃ and 50% relative humidity, the adsorption capacity for formaldehyde ranges from 60-100mg/g.

Superior structural stability: The product employs a high-temperature activation process to enhance the bond between carbon particles and binder, achieving a water absorption rate of ≤5%. It remains non-swelling and non-deforming in high-humidity environments. With wear resistance ≥95%, it prevents carbon powder shedding during prolonged operation, thus avoiding secondary pollution. The service life spans 6-12 months, 2-3 times longer than granular activated carbon.

Easy installation and maintenance: The modular design enables standardized installation, allowing direct assembly into adsorption equipment without specialized fixtures, boosting efficiency by 40%. Complete disassembly during replacement simplifies operations, reduces downtime, and lowers maintenance costs.

Application Fields 1. Industrial Waste Gas Purification: In VOCs treatment for industries such as painting, printing, electronics, and chemicals, 2.0mm-pore honeycomb carbon adsorption towers achieve 85%-95% adsorption efficiency for pollutants including benzene, toluene, and ethyl acetate, with treated emissions compliant with GB 37822-2019 standards. For furniture factory spray painting exhaust, a single unit can process 10,000-50,000 m³/h of air volume, removing 10-50kg of VOCs daily.

Flue Gas Desulfurization and Denitrification: In flue gas treatment systems for coal-fired power plants and waste incineration facilities, honeycomb activated carbon functions as an adsorption-catalytic carrier. It simultaneously adsorbs SO₂ and NOₓ, with a SO₂ adsorption capacity of 60-100mg/g and denitrification efficiency of 35%-55%. The adsorbed SO₂ is converted into ammonium sulfate byproduct, enabling resource recovery.

Indoor Air Treatment: As the core filter material for air purifiers and fresh air systems, the 1.5mm pore product achieves over 80% adsorption efficiency for indoor pollutants such as formaldehyde and TVOC, compatible with both residential and commercial purification devices. For air treatment in newly renovated homes, placing one 100mm×100mm×100mm honeycomb charcoal per 10㎡ space can reduce formaldehyde concentration to below 0.1mg/m³ within 7-15 days, meeting the requirements of GB 50325-2020 standard.

Water Treatment Applications: In advanced drinking water treatment, this process effectively removes odors, residual chlorine, and trace organic compounds, with a treatment capacity of 5-20 m³/ and a residual chlorine removal rate of ≥99%. For industrial wastewater decolorization, it achieves 80%-90% decolorization efficiency and reduces COD levels by 30%-50%, serving as a key advanced treatment unit following biological processes.

Other applications: In automotive exhaust purification, it acts as a catalyst carrier loaded with precious metals to enhance the conversion efficiency of CO and NOₓ in exhaust gases; in underground garage ventilation systems, it adsorbs hydrocarbon pollutants from vehicle emissions to improve air quality; in cold storage preservation, it adsorbs ethylene gas released by fruits and vegetables, extending their freshness by 2-3 times.

Packaging Specifications: The packaging solution features moisture-proof and damage-resistant design. Each product is individually encapsulated with PE film to prevent friction damage during transportation. For multi-unit packaging, the inner layer is separated and cushioned with bubble wrap, while the outer layer uses a five-layer corrugated cardboard box filled with pearl cotton for stabilization, effectively preventing breakage caused by jolts.

Standard packaging specifications: The standard small package contains 10 units per box (100mm×100mm×100mm dimensions, with a gross weight of approximately 7.5kg). The box body is printed with product model, aperture diameter, specific surface area, and other information. Industrial bulk packaging is available in 50-unit boxes or custom pallet packaging (200-500 units per pallet), reinforced with wrapping film for forklift handling. The packaging bears a "Moisture-proof, handle gently, avoid compression" warning label. Industrial-grade and consumer-grade products are distinguished by box color (gray for industrial-grade, blue for consumer-grade). When sealed, the product has a shelf life of 2 years in a cool, dry environment. After opening, it must be resealed and used within 60 days.

Storage Guidelines 1. Storage Requirements: Store in a dedicated dry warehouse with temperature maintained between 0-40°C and relative humidity ≤65%. The warehouse must be equipped with ventilation and moisture-proof facilities, avoiding direct sunlight and proximity to high-temperature sources (e.g., steam pipes, heating equipment). Products should be neatly stacked on wooden pallets, with stacking height not exceeding 1.5 meters to prevent bottom layer damage. Maintain a minimum distance of 15cm from the ground/walls to isolate moisture. Strictly avoid mixing with acids, alkalis, oxidizers, or volatile chemicals. Maintain a minimum storage distance of 8 meters to prevent cross-contamination.

Transportation Requirements: Transport vehicles must be kept dry and clean, with rainproof fabric and moisture-proof padding installed in the cargo compartment. Handle with care during loading and unloading—avoid throwing or squeezing. Use manual or forklift handling, ensuring forks do not impact packaging. Implement rain, sun, and dust protection measures during transit, and never mix with liquid cargo or sharp objects. For long-distance transport, inspect packaging integrity every 200 kilometers, reinforce any damage immediately, and equip vehicles with emergency protective gear.

Usage Guidelines: Before installation, inspect the product's appearance and remove any defective units with missing corners or cracks. Ensure the channel orientation aligns with the fluid flow direction during installation to prevent reverse installation that may impair adsorption performance. For exhaust gas treatment systems, conduct regular monitoring of pollutant concentrations at both inlet and outlet. When adsorption efficiency drops below 40% of the initial value, regeneration or replacement is required. Regeneration should employ high-temperature steam desorption for 6-8 hours. Water wash regeneration is only applicable to water-soluble pollutants, and the unit must be dried after washing before reuse.

Safety Warning: The product has a combustion temperature of 450-500°C. Open flames are strictly prohibited in storage and usage areas. Two 4kg dry powder fire extinguishers must be provided for every 100㎡, with monthly inspections of fire safety equipment. After adsorbing flammable pollutants like VOCs, the saturated carbon must be stored away from fire sources. During regeneration, the heating rate must be controlled (≤5℃/min) to prevent localized overheating and combustion. Discarded saturated carbon must be disposed of by qualified environmental agencies and must not be dumped indiscriminately to avoid soil or water pollution. Operators must wear dust masks and gloves during installation to avoid inhaling carbon powder.