净水活性炭产品专业介绍

净水活性炭是一种以优质天然原料经特殊工艺活化制成的多孔性吸附材料,其核心功能通过发达孔隙结构对水中污染物进行物理吸附与化学截留,实现水质净化。作为水处理领域的关键材料,它凭借稳定的性能和高效的净化能力,广泛应用于生活饮水、工业废水处理等多个场景,是保障水质安全的核心载体之一。

一、外观特征

净水活性炭的外观形态与原料及加工工艺直接相关,主流产品呈现三大类特征:颗粒状产品以椰壳、桃壳等果壳为原料时,多为黑色不规则破碎颗粒,表面粗糙且有自然纹理,粒径常见3-40目,优质椰壳炭颗粒边缘呈钝圆状,无尖锐棱角,手感坚实且无明显粉尘脱落;柱状产品则以煤质或木质原料经挤压成型制成,为黑色圆柱体,直径通常1.5-4mm,长度3-10mm,表面光滑均匀,断面可见细密孔隙结构,机械强度突出;粉状产品为极细黑色粉末,粒径多在200目以上,手感细腻,在水中易分散,需通过滤布或载体固定使用。

所有类型产品均以“黑度均匀、无杂色斑点、无刺激性异味”为优质判定基准,其中椰壳基产品因原料特性,颜色普遍深于煤质或木质产品,且颗粒密度相对更低。

二、核心特性

净水活性炭的性能优势源于其独特的结构与化学属性,核心特性可概括为四大维度:

1. 发达的孔隙结构与超大比表面积:这是其吸附能力的基础,1克优质活性炭的孔隙展开面积可达1000-1350㎡,相当于两个足球场大小。孔隙分为微孔(半径<2nm)、过渡孔(2-100nm)和大孔(>100nm),其中微孔负责吸附小分子有机物,过渡孔加速污染物扩散,形成高效吸附体系,对分子量500-1000的有机物吸附效果最优。

2. 优异的吸附选择性与容量:作为非极性吸附剂,对水中苯类、酚类等非极性有机物吸附能力显著,同时可高效去除游离氯、重金属离子(砷、铅、氰等)、农药残留及致臭物质。关键性能指标中,碘吸附值可达800-1300mg/g,亚甲基蓝吸附值105-240mg/g,四氯化碳吸附率最高90%,确保净化深度。

3. 稳定的物理化学性能:化学性质稳定,耐酸耐碱耐热,在pH值4-11的水体中性能稳定,不溶于水及有机溶剂,不会产生二次污染。颗粒及柱状产品机械强度≥90%,耐冲洗、不易破碎,使用寿命可达6-24个月,且饱和后可通过高温再生恢复部分吸附能力。

4. 高效的动力学特性:吸附速度快,前几小时即可完成60%-80%的吸附容量,过渡孔发达的产品可加速污染物向内扩散,适合水处理中连续运行的需求,尤其在应急水质处理中能快速改善水色与异味。

三、应用领域

基于不同性能优势,净水活性炭形成了覆盖民生与工业的多元应用体系:

1. 生活饮用水净化:椰壳基颗粒炭是核心材料,用于家用净水器、社区净水站及市政水厂,可去除自来水中的余氯(去除率>95%)、消毒副产物前驱体、异臭异味及微量重金属,提升饮水口感与安全性。炭棒滤芯则结合过滤与吸附功能,适用于末端净化。

2. 食品饮料与医药用水处理:在纯净水、矿泉水、酒类及饮料生产中,用于去除原料水中的有机物、色素及异味,保障产品品质;医药行业中用于注射用水、制剂用水的预处理,去除热原及微量污染物,符合GMP标准。

3. 工业废水深度处理:煤质活性炭因成本优势广泛应用于化工、印染、电镀等行业,处理含酚、氰、染料、重金属的废水,如电镀废水除铬、印染废水脱色(脱色率≥70%);木质粉状炭则用于突发污染应急处理,快速吸附藻类毒素及泄漏有机物。

4. 特殊领域净化:电子行业超纯水制备中,用于去除水中痕量有机物,保护反渗透膜;海运及水产养殖中,用于改善养殖水体水质,吸附残饵与排泄物分解产物,维持水体生态平衡。

天源净水活性炭指标基本参数(可按客户需求定制):

型号 | 指标(可定制) | 用途 |

TY-YKL1(椰壳颗粒炭) | 粒度:10-24目 | 用于锅炉水、凝结水、电子半导体行业高纯水精制 |

TY-YKL2(椰壳颗粒炭) | 粒度20-48目 | 净水器滤芯、饮料、酒类、食品、高纯水应用 |

TYK-TKL(桃壳颗粒炭) | 粒度:20-40目 | 用于酒类脱色、提纯,去除苦味改善口感 |

TY-YKF(椰壳粉末炭) | 粒度:150-325目 | 饮用水处理、食品脱色提纯与精制、药剂添加、污水处理、提炼贵金属 |

TY-XKF(杏壳粉末炭) | 粒度:150-325目 | 饮用水处理、污水处理、食品脱色提纯、药剂添加 |

TY-TKF(桃壳粉末炭) | 粒度:150-325目 | 饮用水处理、污水处理 |

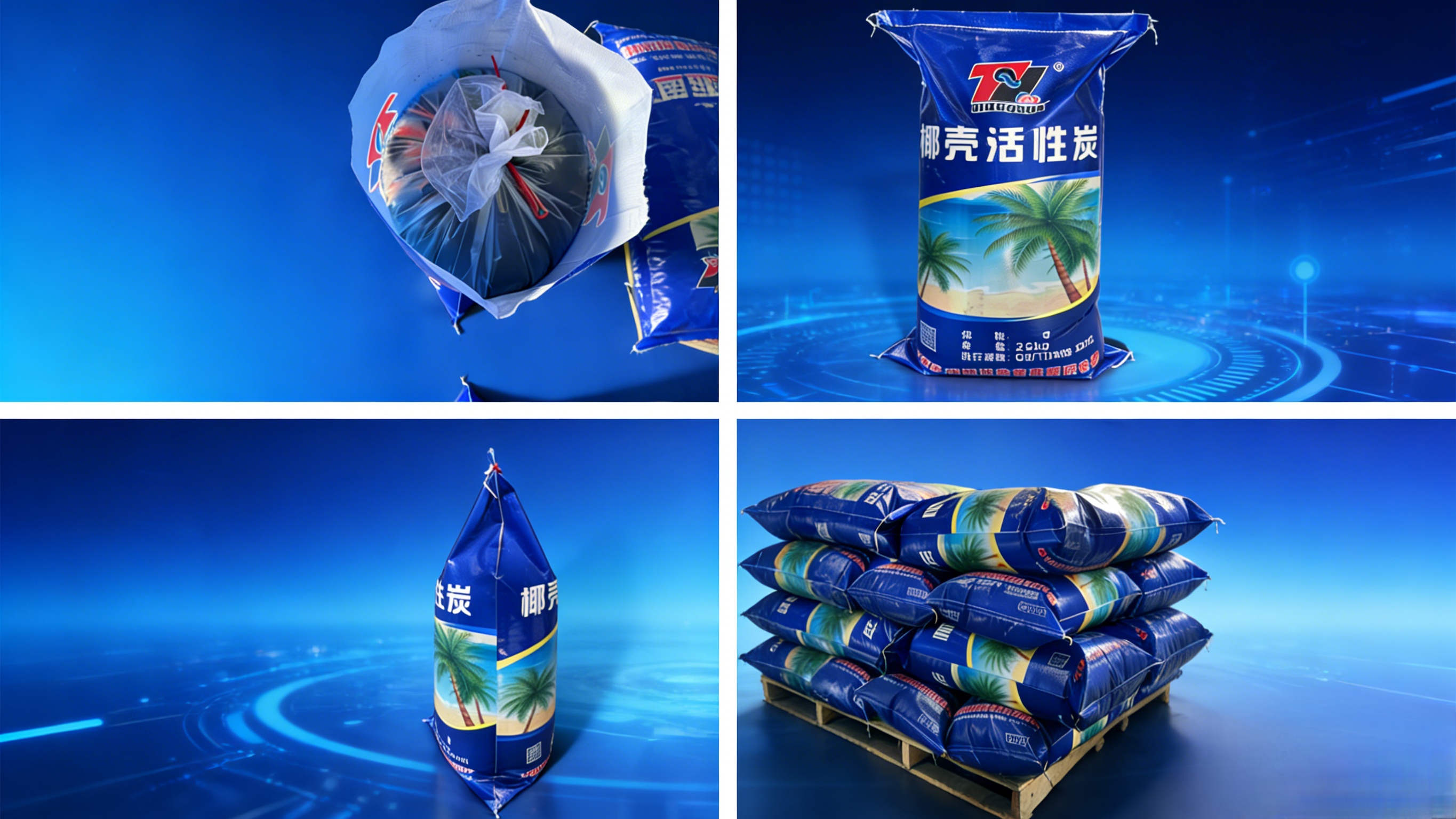

四、包装规格

包装设计以“防潮、防破损、便于储运”为核心,根据应用场景分为三大类:

1. 民用小规格包装:针对家用净水器用户,采用食品级聚乙烯密封袋包装,规格为50g、100g、500g,袋身标注型号、碘值、适用场景及保质期,外层套彩盒防潮,便于零售与储存。

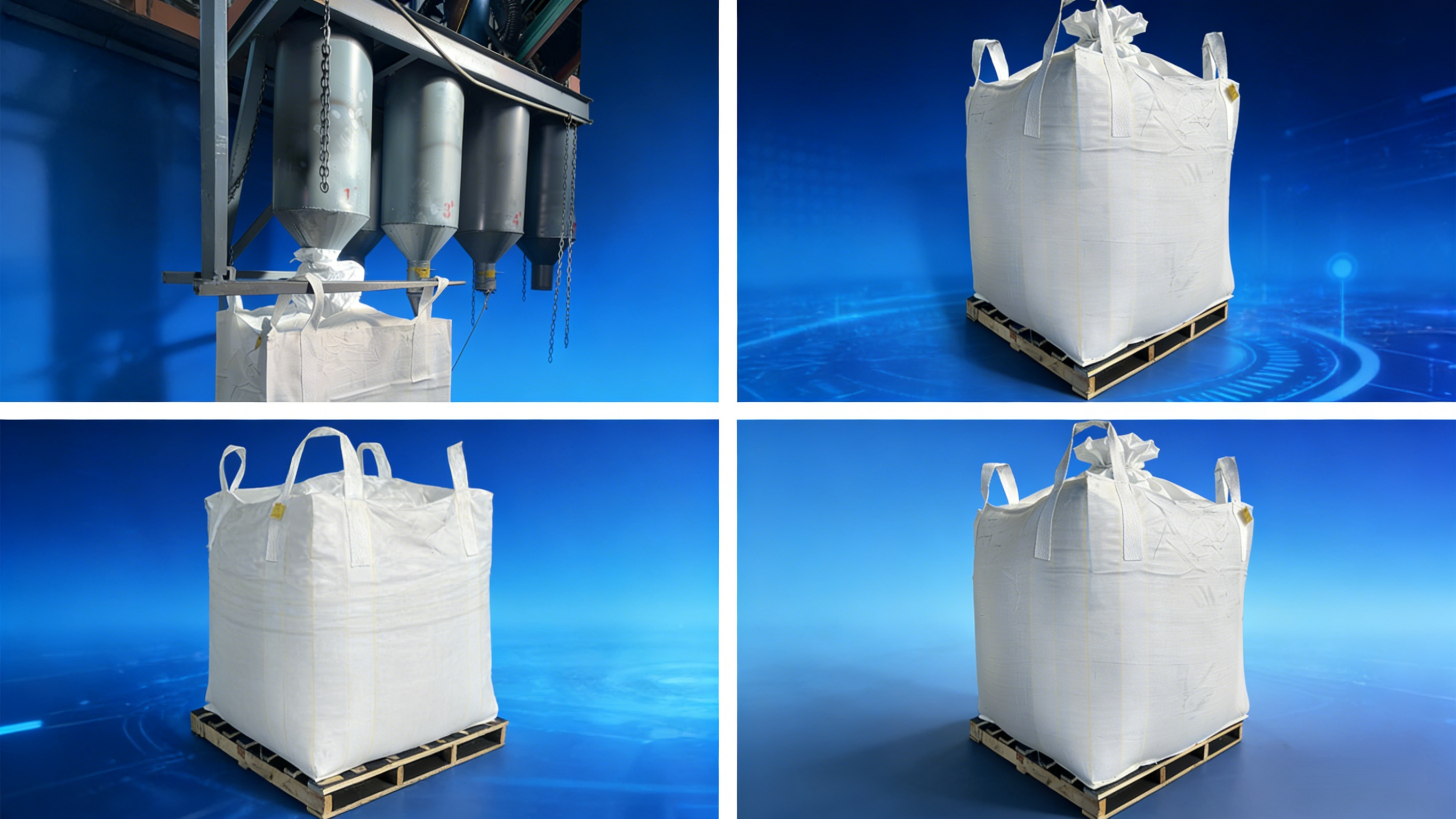

2. 工业常规包装:颗粒及柱状产品采用双层包装,内层为防水塑料膜,外层为聚丙烯编织袋,规格25kg/袋、50kg/袋,部分产品配备吨袋包装(1000kg/袋),袋身印有产品批号、性能指标、防潮标识;粉状产品采用阀口袋包装,防止运输中粉尘泄漏。

3. 定制化包装:针对大型水厂及工业客户,可提供不锈钢密封桶(200kg/桶)或集装箱散装,配备防潮透气阀,同时提供产品质量检测报告与批次追溯信息,满足规模化使用需求。

五、注意事项

为确保净水效果与使用安全,需遵循以下规范:

1. 选型适配:根据处理目标选择产品,饮用水优先选椰壳炭(碘值≥900mg/g),工业废水可选煤质炭;高浊度水体需前置过滤,避免大颗粒杂质堵塞活性炭孔隙。

2. 安装与预处理:新炭使用前需用清水冲洗2-3次,去除表面粉尘;颗粒炭装填时避免压实,保留孔隙空间;过滤器需密封良好,防止水体短路,确保水流与炭层充分接触(接触时间≥5分钟)。

3. 更换与维护:民用炭建议3-6个月更换一次,工业用炭根据水质监测结果(如出水COD升高10%以上)及时更换;定期反洗(水温≤40℃),去除炭层截留的悬浮物,延长使用寿命。

4. 储存与安全:需存放于干燥通风处,避免阳光直射与潮湿环境,防止吸附空气中水分失效;远离强酸强碱,运输中轻拿轻放,防止包装破损导致粉尘污染。

5. 安全提示:虽本身无毒,但不可食用;废弃活性炭需按一般固废处理,饱和工业炭若吸附有毒物质,需按危险废物规范处置。

净水活性炭的性能核心在于“孔隙结构与吸附效率的匹配性”,选择时需以碘值、强度、比表面积等量化指标为依据,结合具体应用场景科学选型,才能充分发挥其水质净化价值。

Product Overview: Water Purification Activated Carbon. This porous adsorption material is produced through specialized activation processes using premium natural raw materials. Its core functionality involves physically adsorbing and chemically intercepting water pollutants via its advanced pore structure, effectively purifying water quality. As a critical material in water treatment, it is widely used in drinking water supply and industrial wastewater treatment due to its stable performance and high purification efficiency, serving as a key component in ensuring water safety.

Physical Characteristics The appearance of activated carbon for water purification is directly determined by its raw materials and manufacturing processes. Mainstream products exhibit three distinct types: Granular products: When made from coconut shells, peach shells, or similar fruit casings, these typically appear as irregular black fragments with a rough surface and natural texture. Their particle size generally ranges from 3 to 40 mesh. Premium coconut shell carbon particles feature rounded edges without sharp corners, offering a firm texture and minimal dust shedding. Columnar products: These cylindrical black objects, typically 1.5-4mm in diameter and 3-10mm in length, are formed by extruding coal or wood materials. They possess a smooth, uniform surface with visible fine pore structures in cross-section and exceptional mechanical strength. Powdered products: These ultra-fine black powders, usually above 200 mesh in particle size, have a delicate texture and are easily dispersible in water. They require fixation using filter cloth or carriers for practical application.

All product types are evaluated for quality based on criteria of "uniform blackness, absence of color spots, and no irritating odors". Coconut shell-based products, due to their raw material characteristics, generally exhibit darker colors than coal or wood products and have relatively lower particle density.

II. Core Characteristics The performance advantages of water purification activated carbon stem from its unique structure and chemical properties, which can be summarized in four key dimensions: 1. Advanced pore structure and ultra-large specific surface area: This forms the basis of its adsorption capacity. One gram of high-quality activated carbon can have a pore expansion area of 1,000-1,350㎡, equivalent to two football fields. The pores are categorized into micropores (radius <2nm), mesopores (2-100nm), and macropores (>100nm). Micropores adsorb small molecular organic compounds, while mesopores accelerate pollutant diffusion, forming an efficient adsorption system that optimally adsorbs organic compounds with molecular weights of 500-1,000.

Exceptional adsorption selectivity and capacity: As a non-polar adsorbent, it demonstrates remarkable adsorption capacity for non-polar organic compounds such as benzene and phenols in water, while effectively removing free chlorine, heavy metal ions (arsenic, lead, cyanide), pesticide residues, and odor-causing substances. Key performance metrics include an iodine adsorption value of 800-1300 mg/g, a methylene blue adsorption value of 105-240 mg/g, and a carbon tetrachloride adsorption rate of up to 90%, ensuring thorough purification.

Stable physicochemical properties: Chemically stable with acid, alkali, and heat resistance. It remains stable in water with pH 4-11, insoluble in water and organic solvents, and non-toxic. The granular and columnar products exhibit mechanical strength ≥90%, are resistant to washing and breakage, with a service life of 6-24 months. After saturation, partial adsorption capacity can be restored through high-temperature regeneration.

High-efficiency kinetic performance: The adsorption process achieves 60%-80% capacity within hours. Products with well-developed transitional pores accelerate pollutant diffusion, meeting continuous operation requirements in water treatment. Particularly effective for emergency water quality treatment, it rapidly improves water clarity and odor.

III. Application Fields Leveraging distinct performance advantages, activated carbon for water purification has developed a diversified application system serving both residential and industrial sectors: 1. Drinking Water Purification: Coconut shell-based granular carbon serves as the core material in household water purifiers, community water stations, and municipal water plants. It effectively removes residual chlorine (removal rate>95%), disinfection byproduct precursors, odors, and trace heavy metals from tap water, thereby enhancing drinking water taste and safety. Carbon rod filter cartridges combine filtration and adsorption functions, making them suitable for end-of-pipe purification.

Water treatment for food, beverage and pharmaceuticals: In the production of purified water, mineral water, alcoholic beverages and drinks, it is used to remove organic compounds, pigments and odors from raw water to ensure product quality. In the pharmaceutical industry, it serves as pretreatment for water used in injections and drug preparations, removing pyrogens and trace contaminants to meet GMP standards.

Advanced industrial wastewater treatment: Coal-based activated carbon, valued for its cost-effectiveness, is extensively utilized in chemical, textile dyeing, and electroplating industries to treat wastewater containing phenols, cyanides, dyes, and heavy metals. For example, it removes chromium from electroplating effluent and decolorizes dyeing wastewater (with decolorization efficiency ≥70%). Meanwhile, wood-based powdered carbon serves as an emergency solution for sudden pollution incidents, rapidly adsorbing algal toxins and leaked organic compounds.

Special field purification: In the preparation of ultrapure water for the electronics industry, it is used to remove trace organic matter in water and protect reverse osmosis membranes; in the maritime transport and aquaculture, it is used to improve the water quality of aquaculture, adsorb residual feed and decomposition products of excreta, and maintain the ecological balance of water.

Packaging Specifications The packaging design focuses on moisture resistance, damage prevention, and ease of storage and transportation, categorized into three types based on application scenarios: 1. Compact Civilian Packaging: Designed for household water purifiers, these food-grade polyethylene sealed bags come in 50g,100g, and 500g sizes. Each bag is labeled with model number, iodine value, application scenarios, and shelf life, and features a color-coated outer box for moisture protection, facilitating retail and storage.

Standard industrial packaging: Granular and cylindrical products are packaged in a double-layer system, with an inner waterproof plastic film and an outer polypropylene woven bag, available in 25kg/50kg sizes. Some products are packaged in 1000kg bags, featuring batch numbers, performance specifications, and moisture-proof labels. Powdered products are packaged in valve bags to prevent dust leakage during transportation.

Customized Packaging: For large water treatment plants and industrial clients, we provide stainless steel sealed drums (200kg per drum) or bulk containers with moisture-proof and breathable valves. We also offer product quality inspection reports and batch traceability information to meet large-scale usage requirements.

Key Considerations To ensure effective water purification and safe usage, the following guidelines must be followed: 1. Model Selection: Choose products based on treatment objectives. For drinking water, prioritize coconut shell charcoal (iodine value ≥900mg/g), while industrial wastewater may use coal-based charcoal. Pre-filtering is required for highly turbid water to prevent clogging of activated carbon pores by large particles.

Installation and Pre-treatment: Before using new charcoal, rinse it with clean water 2-3 times to remove surface dust. When loading granular charcoal, avoid compacting to maintain pore space. Ensure the filter is properly sealed to prevent water short-circuiting, and guarantee sufficient contact time between water flow and charcoal layer (≥5 minutes).

Replacement and Maintenance: Civil carbon should be replaced every 3-6 months, while industrial carbon requires timely replacement based on water quality monitoring results (e.g., COD in effluent increases by over 10%). Regular backwashing (at temperatures ≤40°C) removes suspended solids retained by the carbon layer, thereby extending its service life.

Storage and Safety: Store in a dry and well-ventilated area, avoiding direct sunlight and humid conditions to prevent moisture absorption and loss of effectiveness. Keep away from strong acids and alkalis. Handle with care during transportation to avoid packaging damage and dust contamination.

Safety note: Although non-toxic, it should not be consumed. Spent activated carbon should be disposed of as general solid waste, while saturated industrial carbon containing toxic substances must be handled as hazardous waste.

The performance of water purification activated carbon is based on the matching of pore structure and adsorption efficiency. The selection should be based on the quantitative indexes such as iodine value, strength and specific surface area, and the scientific selection of the type should be combined with the specific application scenarios, so as to give full play to its water purification value.