气相吸附活性炭:气体净化与分离的关键材料

气相吸附活性炭是一类专为气体介质处理设计的多孔炭质吸附材料,凭借发达的微孔结构、超大的比表面积和优异的表面化学特性,在工业尾气治理、室内空气净化、气体分离提纯、防毒防护等领域发挥着不可替代的作用,是实现气体净化、保障生态环境与人体健康的核心材料。

从结构特性来看,气相吸附活性炭与液相吸附活性炭的核心差异在于孔隙分布的精准适配。活性炭的吸附性能由微孔(孔径<2nm)、中孔(2-50nm)和大孔(>50nm)协同决定,而气相吸附活性炭的核心优势在于微孔占比极高,通常可达总孔隙体积的 80% 以上。这是因为气体分子直径普遍较小,微孔能够为其提供充足的吸附位点,同时微孔内的分子间作用力更强,能牢牢捕捉气体分子;大孔和中孔则主要起到 “传输通道” 的作用,加速气体分子向微孔扩散,提升整体吸附效率。此外,气相吸附活性炭的比表面积通常在 800-1500m²/g,部分高端产品甚至可达 2000m²/g 以上,远超液相吸附活性炭,为气体吸附提供了更大的接触面积。

气相吸附活性炭的原料来源丰富,主要包括木质(木屑、木炭)、煤质(无烟煤、烟煤)、果壳(椰壳、杏壳)和有机废料(秸秆、废纸)等。其中,椰壳基气相吸附活性炭因微孔结构发达、孔径均匀、强度高、灰分低,是高端气体净化领域的首选,广泛应用于防毒面具、室内空气净化等场景;煤质气相吸附活性炭则凭借成本低廉、吸附容量大的优势,多用于工业大规模尾气处理。其制备工艺与液相吸附活性炭类似,核心步骤为炭化和活化,但活化工艺更注重微孔的形成:物理活化法(水蒸气、二氧化碳活化)是气相吸附活性炭的主流制备方式,通过高温下活化剂与炭料的反应,刻蚀出大量微孔;化学活化法则适用于制备超高比表面积的产品,常用活化剂为氢氧化钾、磷酸等,不过该方法会产生废水,环保处理成本相对较高。

在吸附原理方面,气相吸附活性炭的作用机制分为物理吸附和化学吸附,且以物理吸附为主。物理吸附基于分子间的范德华力,活性炭表面的微孔如同 “分子捕手”,能将气体中的有害分子(如甲醛、苯、VOCs、硫化氢等)吸附在孔隙内,这个过程可逆,通过脱附再生可实现活性炭的重复利用。化学吸附则是通过对活性炭进行改性处理,在其表面负载特定化学物质(如高锰酸钾、氢氧化钠、金属氧化物等),使这些物质与目标气体分子发生化学反应,形成稳定的化合物。例如,负载高锰酸钾的活性炭可高效去除硫化氢、二氧化硫等酸性气体,负载金属氧化物的活性炭能捕捉甲醛并将其分解为无害物质。此外,气相吸附效果还受温度、压力、气体浓度等因素影响:低温、高压环境更利于物理吸附,而气体浓度越高,吸附速率越快,达到吸附饱和的时间则越短。

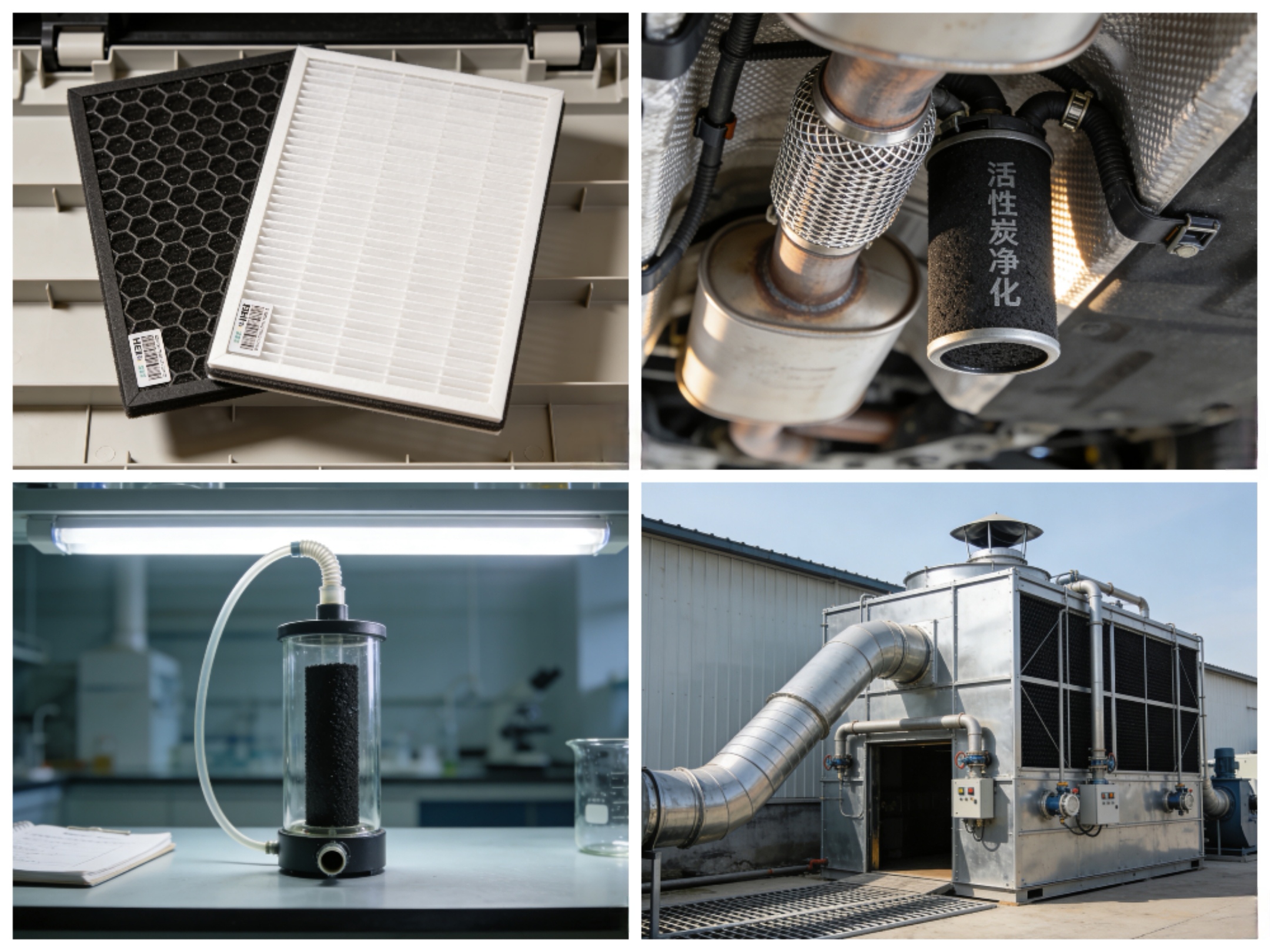

气相吸附活性炭的应用场景覆盖多个关键领域,且不同场景对产品性能的要求各有侧重。在工业尾气治理领域,它可高效去除化工、冶金、涂装等行业排放的 VOCs、硫化氢、二氧化硫、氮氧化物等有害气体,降低尾气对大气的污染,助力企业实现环保达标排放;在室内空气净化方面,常用于空气净化器、活性炭包等产品,吸附甲醛、苯、甲苯等装修污染物,以及油烟异味、宠物异味等,改善室内空气质量;在气体分离提纯中,可用于工业原料气的精制,例如从混合气体中分离甲烷、氢气、二氧化碳等,提升气体纯度;在防毒防护领域,是防毒面具、防毒口罩的核心滤材,能吸附战场上的毒剂蒸汽、核工业中的放射性气体,保障人员生命安全。

再生与资源化利用是气相吸附活性炭降低应用成本、实现绿色发展的核心环节。常见的再生方法包括热再生法、真空脱附法、变压吸附法和化学洗脱法:热再生法是最常用的方式,将饱和活性炭加热至 100-300℃脱附低沸点气体,加热至 600-900℃分解高沸点物质,再生效率可达 90% 以上,且能多次重复使用;真空脱附法和变压吸附法则适用于工业连续化生产场景,通过降低压力或抽真空的方式,实现吸附与脱附的循环操作;化学洗脱法则针对化学吸附饱和的活性炭,通过酸碱溶液洗脱反应产物,不过该方法会产生二次废水。对于无法再生的废炭,可作为燃料回收热能,或作为原料制备炭基复合材料,实现资源的循环利用。

随着环保政策趋严和人们对空气质量要求的提升,气相吸附活性炭的市场需求持续增长,其研发方向正朝着专用化、高效化、绿色化发展。例如,针对特定气体的改性专用活性炭(如甲醛专用炭、VOCs 专用炭)不断涌现;微波活化、等离子体活化等绿色制备技术逐渐替代传统工艺,减少环境污染;而活性炭与光催化材料的复合产品,更是实现了 “吸附 + 分解” 的协同作用,大幅提升气体净化效率。

综上所述,气相吸附活性炭凭借独特的微孔结构和优异的吸附性能,成为气体净化与分离领域的关键材料。从工业尾气治理到室内空气净化,从气体提纯到防毒防护,它在保障生态环境和人体健康方面发挥着重要作用,未来随着技术的不断创新,其应用价值将进一步凸显。

Gas-phase adsorption activated carbon: A pivotal material for gas purification and separation. Specifically engineered for gas medium treatment, this porous carbon-based adsorbent material utilizes its advanced microporous structure, exceptional specific surface area, and superior surface chemical properties. It plays an irreplaceable role in industrial exhaust gas treatment, indoor air purification, gas separation and purification, as well as toxic gas protection. As a core material, it is essential for achieving gas purification and safeguarding both ecological environments and human health.

Structurally, the key distinction between gas-phase adsorption activated carbon and liquid-phase adsorption activated carbon lies in their precise pore distribution. The adsorption performance of activated carbon is determined by three pore types: micropores (<2nm), mesopores (2-50nm), and macropores (>50nm). The core advantage of gas-phase adsorption activated carbon stems from its exceptionally high micropore content, typically exceeding 80% of total pore volume. This is because gas molecules are generally small in diameter, allowing micropores to provide ample adsorption sites. Moreover, the stronger intermolecular forces within micropores enable firm capture of gas molecules. Meanwhile, macropores and mesopores primarily function as "transport channels," accelerating gas diffusion into micropores to enhance overall adsorption efficiency. Additionally, gas-phase adsorption activated carbon boasts a specific surface area of 800-1500 m²/g, with premium products surpassing 2000 m²/g. This significantly outperforms liquid-phase adsorption activated carbon by offering a much larger contact area for gas adsorption.

Gas-phase adsorption activated carbon has diverse raw material sources, primarily including wood-based materials (wood chips, charcoal), coal-based materials (bituminous coal, anthracite), fruit shells (coconut shells, apricot shells), and organic waste (straw, waste paper). Among these, coconut shell-based gas-phase adsorption activated carbon stands out as the preferred choice for high-end gas purification due to its well-developed microporous structure, uniform pore size, high strength, and low ash content. It is widely used in scenarios like gas masks and indoor air purification. Coal-based gas-phase adsorption activated carbon, leveraging its cost-effectiveness and high adsorption capacity, is predominantly applied in large-scale industrial exhaust treatment. Its preparation process resembles liquid-phase adsorption activated carbon, with the core steps being carbonization and activation. However, activation processes place greater emphasis on micropore formation. The physical activation method (using steam or carbon dioxide) is the mainstream preparation approach for gas-phase adsorption activated carbon, where high-temperature reactions between activators and carbon materials etch out numerous micropores. The chemical activation method, while suitable for producing ultra-high specific surface area products, commonly uses activators like potassium hydroxide and phosphoric acid. However, this method generates wastewater, resulting in relatively higher environmental treatment costs.

In terms of adsorption principles, the mechanism of gas-phase adsorption by activated carbon involves both physical and chemical adsorption, with physical adsorption being predominant. Physical adsorption relies on intermolecular van der Waals forces, where the micropores on the activated carbon surface act as "molecular traps" that capture harmful gas molecules (such as formaldehyde, benzene, VOCs, hydrogen sulfide, etc.) within the pores. This process is reversible, allowing the activated carbon to be reused through desorption and regeneration. Chemical adsorption occurs when the activated carbon is modified by loading specific chemical substances (e.g., potassium permanganate, sodium hydroxide, metal oxides) onto its surface, enabling these substances to chemically react with target gas molecules to form stable compounds. For instance, potassium permanganate-loaded activated carbon can efficiently remove acidic gases like hydrogen sulfide and sulfur dioxide, while metal oxide-loaded activated carbon captures formaldehyde and breaks it down into harmless substances. Additionally, gas-phase adsorption efficiency is influenced by factors such as temperature, pressure, and gas concentration: low temperatures and high pressure environments favor physical adsorption, while higher gas concentrations accelerate the adsorption rate and shorten the time required to reach adsorption saturation.

Activated carbon adsorption technology finds applications across multiple critical sectors, each with distinct performance requirements. In industrial exhaust treatment, it effectively removes harmful gases such as volatile organic compounds (VOCs), hydrogen sulfide, sulfur dioxide, and nitrogen oxides emitted by chemical, metallurgical, and coating industries, reducing atmospheric pollution and helping enterprises achieve environmental compliance. For indoor air purification, it is commonly used in air purifiers and activated carbon packs to adsorb renovation pollutants like formaldehyde, benzene, and toluene, as well as odors from cooking fumes and pets, thereby improving indoor air quality. In gas separation and purification, it refines industrial feedstocks by separating methane, hydrogen, and carbon dioxide from mixed gases, enhancing gas purity. In toxic gas protection, it serves as the core filter material in gas masks and respirators, adsorbing toxic vapors from chemical warfare and radioactive gases in nuclear industries to safeguard personnel safety.

Regeneration and resource recovery are pivotal for reducing operational costs and achieving sustainable development in gas-phase adsorption activated carbon applications. Common regeneration methods include thermal regeneration, vacuum desorption, pressure swing adsorption (PSA), and chemical elution. Thermal regeneration remains the most widely used approach, where saturated activated carbon is heated to 100-300°C to desorb low-boiling gases and 600-900°C to decompose high-boiling substances, achieving over 90% regeneration efficiency with multiple reuse cycles. Vacuum desorption and PSA are ideal for industrial-scale production, enabling cyclic adsorption-desorption operations through pressure reduction or vacuum extraction. Chemical elution targets chemically saturated activated carbon by washing off reaction products with acid or alkali solutions, though this method generates secondary wastewater. For non-regenerable waste carbon, thermal energy can be recovered as fuel, or it can be repurposed as raw material for carbon-based composite materials, ensuring resource recycling.

With increasingly stringent environmental policies and heightened public demand for air quality, the market for gaseous adsorption activated carbon continues to expand. Its R&D is now focusing on specialization, efficiency, and eco-friendliness. For instance, specialized modified activated carbon for specific gases (such as formaldehyde-specific and VOCs-specific carbon) is increasingly being developed. Green preparation technologies like microwave activation and plasma activation are gradually replacing traditional methods to reduce environmental pollution. Moreover, composite products combining activated carbon with photocatalytic materials have achieved a synergistic "adsorption + decomposition" effect, significantly enhancing gas purification efficiency.

In summary, gas-phase adsorption activated carbon has emerged as a pivotal material in gas purification and separation due to its unique microporous structure and exceptional adsorption capabilities. From industrial exhaust treatment to indoor air purification, and from gas refinement to toxic substance prevention, it plays a vital role in safeguarding both ecological environments and human health. With continuous technological advancements, its application value is poised to grow even more significantly in the future.