液相吸附活性炭是一种专门针对液体介质进行吸附净化的功能性炭材料,凭借发达的孔隙结构、优异的吸附性能和化学稳定性,广泛应用于饮用水处理、工业废水净化、食品饮料提纯、医药精制等多个领域,是液相体系中去除杂质、异味、色素及有毒有害物质的核心材料。从结构特性来看,液相吸附活性炭与气相吸附活性炭的核心区别在于孔隙分布的针对性设计。活性炭的吸附性能由微孔(孔径<2nm)、中孔(孔径 2-50nm)和大孔(孔径>50nm)共同决定:微孔负责吸附小分子物质,大孔起到吸附质传输通道的作用,而液相吸附活性炭的中孔占比更高,这是因为液体中的污染物分子通常尺寸更大,且液体分子间作用力更强,中孔结构能够为大分子污染物提供充足的吸附位点,同时加速液体在炭材料内部的扩散速率,提升吸附效率。

综上所述,液相吸附活性炭凭借独特的结构优势和优异的吸附性能,成为液相介质净化领域不可或缺的材料。从民生饮用水安全到工业废水治理,从食品医药精制到环保产业升级,它都发挥着关键作用,未来随着技术的不断创新,其应用范围和市场价值将进一步提升。

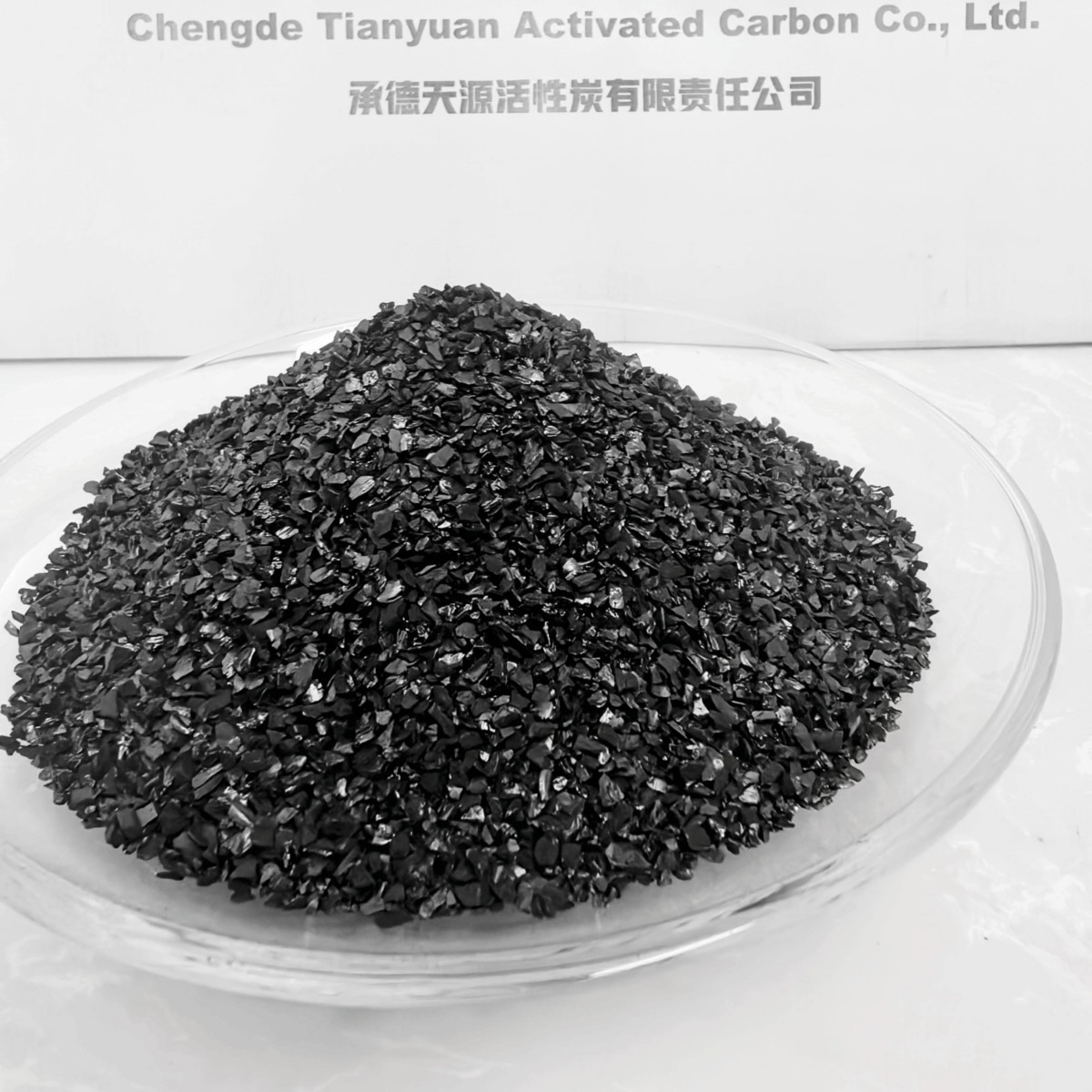

Liquid-phase adsorption activated carbon: The core material for water purification and solution refinement. This specialized functional carbon material is designed for liquid medium adsorption and purification. With its well-developed pore structure, outstanding adsorption capacity, and chemical stability, it is widely used in drinking water treatment, industrial wastewater purification, food and beverage refinement, pharmaceutical processing, and other fields. It serves as the essential material for removing impurities, odors, pigments, and toxic substances in liquid systems.

Structurally, the key distinction between liquid-phase adsorption activated carbon and gas-phase adsorption activated carbon lies in their specifically designed pore distribution. The adsorption performance of activated carbon is determined by three pore types: micropores (diameter <2nm), mesopores (2-50nm), and macropores (>50nm). Micropores adsorb small molecules, while macropores act as transport channels for adsorbates. Liquid-phase adsorption activated carbon exhibits a higher proportion of mesopores, as liquid pollutants are typically larger in size and experience stronger intermolecular forces. The mesoporous structure provides ample adsorption sites for macromolecular pollutants while accelerating liquid diffusion within the carbon material, thereby enhancing adsorption efficiency.

Liquid-phase adsorption activated carbon is sourced from diverse materials, primarily wood-based (wood chips, coconut shells), coal-based (bituminous coal, lignite), and fruit shell-derived (coconut shells, walnut shells). Coconut shell-based variants are preferred for high-end applications like drinking water treatment and food/pharmaceutical industries due to their uniform pore structure, high strength, and low ash content. Coal-based variants, valued for their cost-effectiveness and high adsorption capacity, are widely used in large-scale industrial wastewater treatment. The production process involves two core steps: carbonization and activation. Carbonization involves heating raw materials to 400-600°C in an oxygen-free environment to decompose them into carbonaceous materials. Activation creates numerous internal pores through physical methods (e.g., steam or CO₂ activation) or chemical methods (e.g., zinc chloride or phosphoric acid impregnation). The activation degree directly determines the adsorption performance of the activated carbon.

In terms of adsorption principles, liquid-phase adsorption of activated carbon primarily operates through physical and chemical mechanisms, with physical adsorption being the dominant process. Physical adsorption relies on intermolecular van der Waals forces, where the abundant pores on the activated carbon surface act as "adsorption traps" that firmly capture pollutant molecules from liquids. This reversible process allows for the regeneration and reuse of activated carbon through desorption. Chemical adsorption utilizes oxygen-containing functional groups (such as hydroxyl, carboxyl, and carbonyl groups) on the activated carbon surface to chemically bond with pollutants, forming stable chemical bonds. This method is particularly effective for removing heavy metal ions and polar organic compounds that are difficult to remove through physical adsorption. Additionally, factors such as temperature, pH, contact time, and pollutant concentration significantly influence the liquid-phase adsorption process: lower temperatures favor physical adsorption, acidic conditions enhance adsorption efficiency for cationic pollutants, while extended contact time and reduced pollutant concentration effectively increase the adsorption saturation capacity.

Liquid-phase adsorption activated carbon finds applications across multiple industries, with performance requirements varying significantly across different scenarios. In drinking water treatment, it effectively removes residual chlorine, odors, coloration, and trace organic pollutants (such as pesticide residues and disinfection byproducts), ensuring both safety and taste compliance with national drinking water hygiene standards. For industrial wastewater treatment, it enables targeted adsorption of dye molecules in textile printing wastewater, heavy metal ions in electroplating wastewater, and organic solvents in chemical wastewater, reducing COD and BOD levels to meet discharge standards or enable reclaimed water reuse. In the food and beverage sector, it is commonly used for sugar decolorization, alcohol purification, and juice clarification to eliminate impurities and off-flavors, thereby enhancing product quality. In pharmaceutical applications, it serves as an adsorbent for drug refinement, removing impurities and pyrogens from active pharmaceutical ingredients to ensure drug purity.

Notably, the regeneration and resource recovery of liquid-phase adsorbed activated carbon are critical for reducing operational costs and achieving environmental sustainability. Common regeneration methods include thermal regeneration, chemical regeneration, and biological regeneration. Thermal regeneration involves heating saturated activated carbon to 800-1000°C to decompose and volatilize adsorbed pollutants while restoring pore structure, with a regeneration efficiency of 80%-90% – currently the most widely used method. Chemical regeneration employs acid/alkali solutions or oxidants to remove contaminants, suitable for small-scale, low-concentration wastewater treatment. Biological regeneration utilizes microbial degradation to break down organic pollutants on the carbon surface, offering advantages like low energy consumption and environmental friendliness, though requiring longer regeneration cycles. Regenerated activated carbon can be reused, while non-regenerable waste carbon can be recycled as fuel for thermal energy recovery or as raw material for building materials production, achieving resource circularity.

With increasingly stringent environmental regulations and the advancement of high-end manufacturing, the demand for liquid-phase adsorption activated carbon continues to grow, driving its R&D toward higher performance, specialization, and eco-friendliness. For instance, modified activated carbon targeting specific pollutants—such as photocatalytic variants loaded with nano-TiO₂ or heavy metal adsorption variants loaded with chelating agents—is gaining traction. Green activation techniques like microwave and ultrasonic activation are gradually replacing traditional chemical methods to minimize secondary pollution. Furthermore, the integration of intelligent adsorption systems with activated carbon has enabled automated control in liquid-phase purification processes, significantly enhancing both efficiency and stability.

In summary, liquid-phase adsorption activated carbon has become an indispensable material in liquid-phase purification due to its unique structural advantages and outstanding adsorption performance. It plays a crucial role across various fields—from ensuring drinking water safety for public welfare to industrial wastewater treatment, from food and pharmaceutical refinement to environmental protection industry upgrades. With continuous technological innovation, its application scope and market value are expected to expand further in the future.